Nissan Juke Service and Repair Manual : P0745 pressure control solenoid A

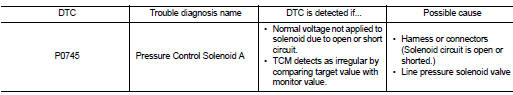

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE

:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Start engine and wait at least 5 seconds.

3. Select “Self Diagnostic Results” in “TRANSMISSION”.

With GST

With GST

Follow the procedure “With CONSULT-III”.

Is “P0745” detected? YES >> Go to TM-219, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

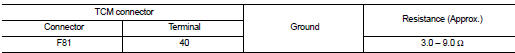

1.CHECK LINE PRESSURE SOLENOID VALVE CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

3. Check resistance between TCM connector terminal and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK LINE PRESSURE SOLENOID VALVE

Check line pressure solenoid valve. Refer to TM-220, "Component Inspection" Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace damaged parts.

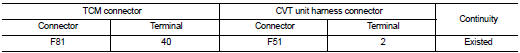

3. CHECK HARNESS BETWEEN TCM AND LINE PRESSURE SOLENOID VALVE

1. Turn ignition switch OFF.

2. Disconnect CVT unit harness connector and TCM connector.

3. Check continuity between TCM connector terminal and CVT unit harness connector terminal.

4. If OK, check harness for short to ground and short to power.

5. If OK, check continuity between ground and CVT assembly.

6. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

Component Inspection

LINE PRESSURE SOLENOID VALVE

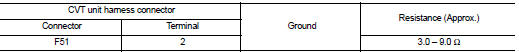

1.LINE PRESSURE SOLENOID VALVE

1. Turn ignition switch OFF.

2. Disconnect CVT unit harness connector.

3. Check resistance between CVT unit harness connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the transaxle assembly. Refer to TM-301, "Removal and Installation"

P0744 torque converter

P0744 torque converter

Description

This malfunction is detected when the torque converter clutch does not

lock-up as instructed by the TCM. This

is not only caused by electrical malfunction (circuits open or shorted), b ...

P0746 pressure control solenoid A

P0746 pressure control solenoid A

Description

The line pressure solenoid valve regulates the oil pump discharge pressure to

suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

D ...

Other materials:

Drive belt idler pulley

Removal and Installation

REMOVAL

1. Remove drive belt. Refer to EM-155, "Removal and Installation".

2. Remove the lock nut, and then remove the plate (7), idler pulley

(6), and washer (5).

1 : Alternator bracket

3. Remove the center shaft (2) together with the spacer (3) with

insert ...

Water outlet

Exploded View

1. Engine coolant temperature sensor

2. Clamp

3. Gasket

4. Clamp

5. Bracket

6. Clamp

7. Water outlet

8. Clamp

9. Clamp

10. Washer

A. To electric throttle control actuator

B. To radiator

C. To CVT oil warmer

D. To heater core

E. To electric throttle control act ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...