Nissan Juke Service and Repair Manual : P0744 torque converter

Description

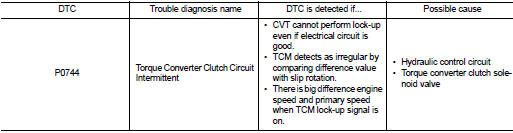

This malfunction is detected when the torque converter clutch does not lock-up as instructed by the TCM. This is not only caused by electrical malfunction (circuits open or shorted), but also by mechanical malfunction such as control valve sticking, improper solenoid valve operation, etc.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” in “TRANSMISSION”.

3. Start engine and maintain the following condition for at least 30 seconds.

ACC PEDAL OPEN : More than 1.0/8

RANGE : “D” position

VEHICLE SPEED : Constant speed of more than 40

km/h (25 MPH)

4. If DTC is detected

With GST

With GST

Follow the procedure “With CONSULT-III”.

Is “P0744” detected? YES >> Go to TM-217, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

1.CHECK LINE PRESSURE

Perform line pressure test. Refer toTM-188, "Inspection and Judgment".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace damaged parts. Refer to TM-188, "Inspection and Judgment".

2.CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

Check torque converter clutch solenoid valve. Refer to TM-216, "Component Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK LOCK-UP SELECT SOLENOID VALVE

Check lock-up select solenoid valve. Refer to TM-248, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK SECONDARY SPEED SENSOR SYSTEM

Check secondary speed sensor system. Refer to TM-209, "DTC Logic".

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5.CHECK PRIMARY SPEED SENSOR SYSTEM

Check primary speed sensor system. Refer to TM-207, "DTC Logic".

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace damaged parts.

6.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

P0730 incorrect gear ratio

P0730 incorrect gear ratio

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds befo ...

P0745 pressure control solenoid A

P0745 pressure control solenoid A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds befo ...

Other materials:

Engine Oils

Prolonged and repeated contact with used engine oil may cause skin cancer.

Try to avoid direct skin contact

with used oil.

If skin contact is made, wash thoroughly with soap or hand cleaner as soon as

possible.

HEALTH PROTECTION PRECAUTIONS

• Avoid prolonged and repeated contact with oils, ...

SRS air bag warning lamp does not turn off

Diagnosis Procedure

1.CHECK AIR BAG MODULE AND SEAT BELT PRE-TENSIONER

Check the deployment of air bag module.

Is air bag module deployed?

YES >> Replace the malfunctioning parts.

NO >> GO TO 2.

2.CHECK AIR BAG FUSE

Check 10 A fuse [No.2, located in fuse block (J/B)].

Is ...

B1116 satellite sensor RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...