Nissan Juke Service and Repair Manual : P0730 incorrect gear ratio

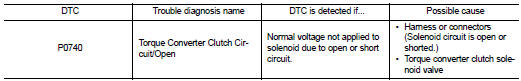

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

NOTE

:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Wait at least 10 consecutive seconds.

3. Select “Self Diagnostic Results” in “TRANSMISSION”.

With GST

With GST

Follow the procedure “With CONSULT-III”.

Is “P0740” detected? YES >> Go to TM-215, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

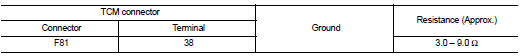

1. CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect TCM connector.

3. Check resistance between TCM connector terminal and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

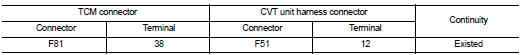

2. CHECK HARNESS BETWEEN TCM AND TORQUE CONVERTER CLUTCH SOLENOID VALVE

1. Disconnect CVT unit harness connector.

2. Check continuity between TCM connector terminal and CVT unit harness connector terminal.

3. If OK, check harness for short to ground and short to power.

4. If OK, check continuity between ground and transaxle assembly.

5. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace damaged parts.

3.CHECK TORQUE CONVERTER CLUTCH SOLENOID VALVE

Check torque converter clutch solenoid valve. Refer to TM-216, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

Component Inspection

TORQUE CONVERTER CLUTCH SOLENOID VALVE

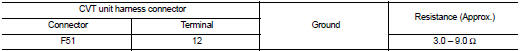

1.TORQUE CONVERTER CLUTCH SOLENOID VALVE

1. Turn ignition switch OFF.

2. Disconnect CVT unit harness connector.

3. Check resistance between CVT unit harness connector terminal and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the transaxle assembly. Refer to TM-301, "Removal and Installation".

P0730 incorrect gear ratio

P0730 incorrect gear ratio

Description

TCM selects the gear ratio using the engine load (throttle position), the

primary pulley revolution speed, and

the secondary pulley revolution speed as input signal. Then it changes th ...

P0744 torque converter

P0744 torque converter

Description

This malfunction is detected when the torque converter clutch does not

lock-up as instructed by the TCM. This

is not only caused by electrical malfunction (circuits open or shorted), b ...

Other materials:

Normal operating condition

Description

FUEL CUT CONTROL (AT NO LOAD AND HIGH ENGINE SPEED)

If the engine speed is above 2,400 rpm under no load (for example, the shift

lever position is neutral and

engine speed is over 2,400 rpm) fuel will be cut off after some time. The exact

time when the fuel is cut off varies

base ...

Air cleaner and air duct

Exploded View

1. Turbocharger air inlet pipe

2. Clamp

3. Air duct (suction)

4. Air mass flow sensor

5. O-ring

6. Air duct (inlet)

7. Grommet

8. Air cleaner case

9. Air cleaner filter

10. Cover

11. Holder

A. : To turbocharger

: Vehicle front

: N·m (kg-m, in-lb)

: Always replac ...

Filament

Inspection and Repair

INSPECTION

1. When measuring voltage, wrap tin foil around the top of the negative

probe. Then press the foil against the wire with your finger.

2. Attach probe circuit tester (in Volt range) to middle portion of

each filament.

3. If a filament is burned out, circuit ...