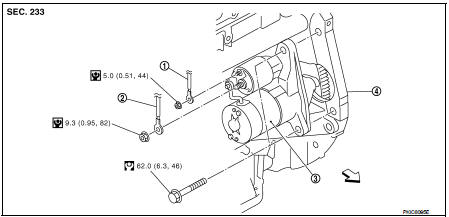

Nissan Juke Service and Repair Manual : MR16DDT : Exploded View

REMOVAL

1. “S” terminal harness

2. “B” terminal harness

3. Starter motor

4. Cylinder block

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

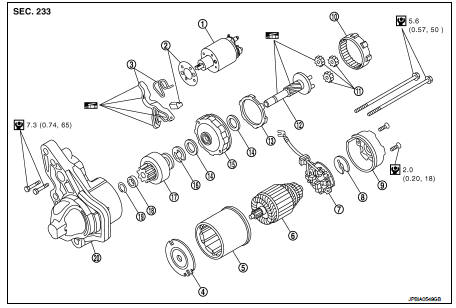

DISASSEMBLY

Type: S114-902

1. Magnetic switch assembly

2. Dust cover kit

3. Shift lever set

4. Center bracket (A)

5. Yoke assembly

6. Armature assembly

7. Brush holder assembly

8. Thrust washer

9. Rear cover assembly

10. Internal gear

11. Planetary gear

12. Pinion shaft

13. Packing

14. Thrust washer

15. Center bracket (P)

16. E-ring

17. Pinion assembly

18. Pinion stopper

19. Pinion stopper clip

20. Gear case assembly

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: High-temperature grease point

: High-temperature grease point

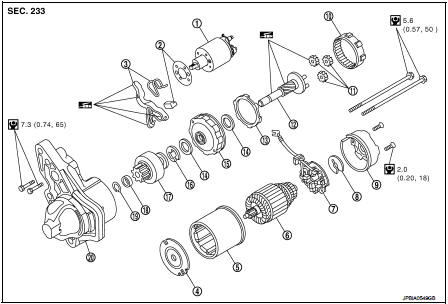

Type: S114-955

1. Magnetic switch assembly

2. Dust cover kit

3. Shift lever set

4. Center bracket (A)

5. Yoke assembly

6. Armature assembly

7. Brush holder assembly

8. Thrust washer

9. Rear cover assembly

10. Internal gear

11. Planetary gear

12. Pinion shaft

13. Packing

14. Thrust washer

15. Center bracket (P)

16. E-ring

17. Pinion assembly

18. Pinion stopper

19. Pinion stopper clip

20. Gear case assembly

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: High-temperature grease point

: High-temperature grease point

NOTE

:

Apply high-temperature grease to lubricate the bearing, gears and frictional

surface when assembling the

starter.

HR16DE : Inspection and Adjust

HR16DE : Inspection and Adjust

INSPECTION

Magnetic Switch Check

• Before starting to check, disconnect the battery cable from the negative

terminal.

• Disconnect “M” terminal of starter motor.

1. Continuity test [between “S ...

MR16DDT : Removal and Installation

MR16DDT : Removal and Installation

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124,

"Removal and Installation".

2. Drain engine coolant from radiator. Refer to CO-11, "Draining&quo ...

Other materials:

B20A0 cranking request circuit

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B20A0 is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to PCS-

30, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Perform DTC CONFIRMATION PROCEDURE for DTC P1650. Re ...

PTC heater

Component Function Check

1.CHECK PTC HEATER OPERATION

1. Start the engine.

2. Operate fan control dial.

3. Operate temperature control dial to full hot position.

4. Check for warm air at discharge air outlet.

NOTE:

• Engine must be cold.

• Battery must be charged.

Is the inspection resu ...

Rear seats

Folding

Before folding the rear seats:

Secure the seat belts on the seat belt hooks on the side wall. (See “Seat belt

hooks” .) To fold the seatback, pull the adjusting knob1 .

To return the seatback to the seating position, lift up each seatback and push

it to the upright position until it ...