Nissan Juke Service and Repair Manual : P0705 transmission range switch A

DTC Logic

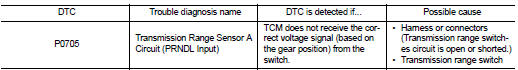

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE

:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignition switch

OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR”.

3. Start engine.

4. Drive vehicle and maintain the following conditions for at least 2 consecutive seconds.

VEHICLE SPEED : More than 10 km/h (6 MPH) ENG SPEED : More than 450 rpm ACC PEDAL OPEN : More than 1.0/8

With GST

With GST

Follow the procedure “With CONSULT-III”.

Is “P0705” detected? YES >> Go to TM-200, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

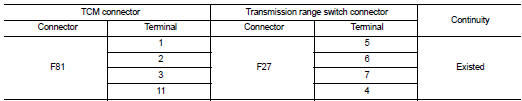

1. CHECK HARNESS BETWEEN TCM AND TRANSMISSION RANGE SWITCH

1. Turn ignition switch OFF.

2. Disconnect TCM connector and transmission range switch connector.

3. Check continuity between TCM connector terminals and transmission range switch connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace damaged parts.

2. DETECT MALFUNCTIONING ITEM

Check the following items.

• Harness for short or open between ignition switch and transmission range switch.

• 10A fuse (No. 55, located in the IPDM E/R).

• Ignition switch.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace damaged parts.

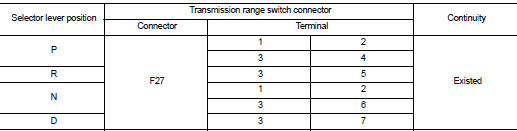

3. CHECK TRANSMISSION RANGE SWITCH

Check transmission range switch. Refer to TM-201, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

Component Inspection

1.CHECK TRANSMISSION RANGE SWITCH

Check continuity between transmission range switch connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK CVT POSITION

1. Disconnect control cable.

2. Check transmission range switch. (Refer to step 1 above.) Is the inspection result normal? YES >> Adjust CVT position. Refer to TM-194, "Inspection and Adjustment".

NO >> GO TO 3.

3.CHECK TRANSMISSION RANGE SWITCH

1. Remove transmission range switch. Refer to TM-278, "Removal and Installation".

2. Check transmission range switch. (Refer to step 1 above.) Is the inspection result normal? YES >> Adjust transmission range switch. Refer to TM-278, "Inspection and Adjustment".

NO >> Replace transmission range switch. Refer to TM-278, "Removal and Installation".

P0703 brake switch B

P0703 brake switch B

Description

BCM detects ON/OFF state of the stop lamp switch and transmits the data to

the CVT control unit via CAN

communication by converting the data to a signal.

DTC Logic

DTC DETECTION LOGI ...

P0710 transmission fluid temperature sensor A

P0710 transmission fluid temperature sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignit ...

Other materials:

P0705 transmission range switch A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE WORK

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next test.

> ...

Stall test

Inspection and Judgment

INSPECTION

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the

CVT fluid temperature is 50 to 80°C (122 to 176°F). Inspect the

amount of CVT fluid. Replenish if necessary.

3. Secu ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...