Nissan Juke Service and Repair Manual : P0710 transmission fluid temperature sensor A

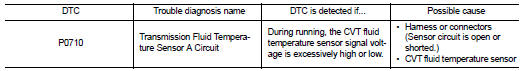

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR” in “TRANSMISSION”.

3. Start engine and maintain the following conditions for at least 10 minutes (Total).

VEHICLE SPEED : 10 km/h (6 MPH) or more ENG SPEED : 450 rpm more than ACC PEDAL OPEN : More than 1.0/8 RANGE : “D” position

With GST

With GST

Follow the procedure “With CONSULT-III”.

Is “P0710” detected? YES >> Go to TM-202, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

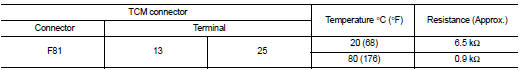

1. CHECK CVT FLUID TEMPERATURE SENSOR CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect the TCM connector.

3. Check resistance between TCM connector terminals.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

2. CHECK CVT FLUID TEMPERATURE SENSOR

Check CVT fluid temperature sensor. Refer to TM-203, "Component Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace the transaxle assembly. Refer to TM-301, "Removal and Installation".

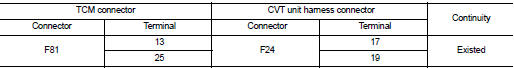

3. CHECK HARNESS BETWEEN TCM AND CVT FLUID TEMPERATURE SENSOR

1. Disconnect the CVT unit harness connector.

2. Check continuity between TCM connector terminals and CVT unit harness connector terminals.

3. If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4.CHECK TCM

Check TCM input/output signals. Refer to TM-164, "Reference Value".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the TCM. Refer to TM-280, "Removal and Installation".

Component Inspection

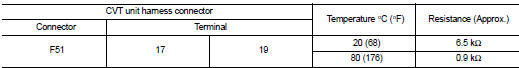

CVT FLUID TEMPERATURE SENSOR

1.CHECK CVT FLUID TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect CVT unit harness connector.

3. Check resistance between CVT unit harness connector terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the transaxle assembly. Refer to TM-301, "Removal and Installation".

P0705 transmission range switch A

P0705 transmission range switch A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignit ...

P0715 input speed sensor A

P0715 input speed sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignit ...

Other materials:

C1111 ABS motor, motor relay system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

C1101, C1102, C1103, C1104 WHEEL SENSOR

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

P158A ECM

DTC Logic

*: Since this DTC is detected when G sensor calibration is incomplete, there

is not replacement parts.

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition swit ...