Nissan Juke Service and Repair Manual : P0715 input speed sensor A

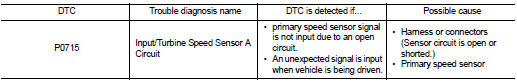

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn ignition switch OFF and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

1.CHECK DTC DETECTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “DATA MONITOR”.

3. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED : 10 km/h (6 MPH) or more

ACC PEDAL OPEN : More than 1.0/8

RANGE : “D” position

ENG SPEED : 450 rpm or more

Driving location : Driving the vehicle uphill (increased

engine load) will help

maintain the driving conditions

required for this test.

With GST

With GST

Follow the procedure “With CONSULT-III”.

Is “P0715” detected? YES >> Go to TM-204, "Diagnosis Procedure".

NO >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

Diagnosis Procedure

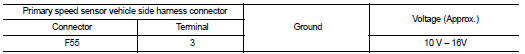

1. CHECK POWER AND SENSOR GROUND

1. Turn ignition switch OFF.

2. Disconnect the primary speed sensor harness connector.

3. Turn ignition switch ON.

4. Check voltage between primary speed sensor harness connector terminals.

Is the inspection result normal? YES >> GO TO 2.

NO >> GO TO 6.

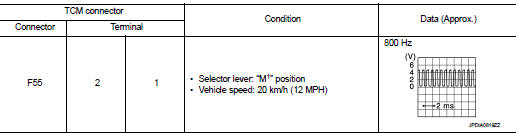

2. CHECK TCM INPUT SIGNAL

1. Turn ignition switch OFF.

2. Connect the primary speed sensor harness connector.

3. Start engine.

4. Lift up the vehicle.

5. Check frequency of primary speed sensor.

Is the inspection result normal? YES >> GO TO 9.

NO >> GO TO 3.

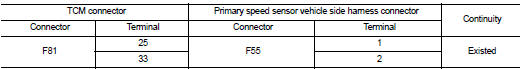

3. CHECK HARNESS BETWEEN TCM AND PRIMARY SPEED SENSOR (PART 1)

1. Turn ignition switch OFF.

2. Disconnect TCM connector and primary speed sensor harness connector.

3. Check continuity between TCM connector terminal and primary speed sensor harness connector terminal.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace damaged parts.

4. CHECK HARNESS BETWEEN TCM AND PRIMARY SPEED SENSOR (PART 2)

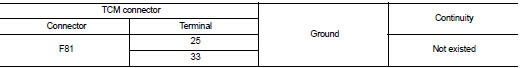

Check continuity between TCM connector terminal and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace damaged parts.

5. CHECK CVT UNIT CIRCUIT

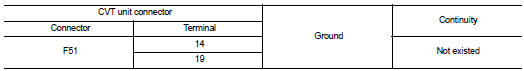

1. Disconnect CVT unit connector.

2. Check continuity between CVT unit connector terminals and ground.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace damaged parts.

6. CHECK HARNESS BETWEEN PRIMARY SPEED SENSOR (POWER) AND IPDM E/R (PART 1)

1. Turn ignition switch OFF.

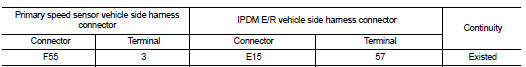

2. Disconnect IPDM E/R connector.

3. Check continuity between primary speed sensor vehicle side harness connector terminal and IPDM E/R vehicle side harness connector terminal.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace damaged parts.

7. CHECK HARNESS BETWEEN PRIMARY SPEED SENSOR (POWER) AND IPDM E/R (PART 1)

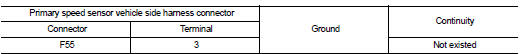

Check continuity between primary speed sensor vehicle side harness connector terminal and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace damaged parts.

8.DETECT MALFUNCTIONING ITEMS

Check the following. Refer to PG-15, "Wiring Diagram - IGNITION POWER SUPPLY -".

• IPDM E/R

• 10A fuse (No.55, located in the IPDM E/R)

• Harness for short or open between IPDM E/R and ignition switch

• Ignition switch

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident" NO >> Repair or replace damaged parts.

9.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace primary speed sensor. Refer to TM-290, "Removal and Installation".

NO >> Repair or replace damaged parts.

P0710 transmission fluid temperature sensor A

P0710 transmission fluid temperature sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignit ...

P0717 input speed sensor A

P0717 input speed sensor A

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATION PROCEDURE” has been previously performed, always turn

ignit ...

Other materials:

HR16DE : Removal and Installation

REMOVAL

1. Disconnect the battery cable from the negative terminal. Refer to PG-124,

"Removal and Installation".

2. Remove radiator reservoir tank. Refer to CO-17, "Exploded View".

3. Disconnect harness connectors (1) from battery terminal with

fusible link.

4. Remove harn ...

P0078 EVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...

P0340 CMP sensor (phase)

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643. Refer to

EC-686, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

...