Nissan Juke Service and Repair Manual : Back door request switch

Component Function Check

1.CHECK FUNCTION

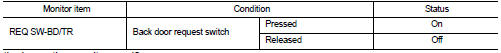

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-BD/TR” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Back door request switch is OK.

NO >> Refer to DLK-71, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BACK DOOR REQUEST SWITCH INPUT SIGNAL

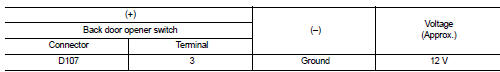

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

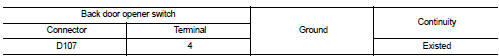

3. Check voltage between back door opener switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK BACK DOOR REQUEST SWITCH CIRCUIT

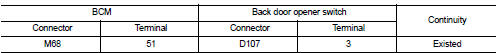

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and back door opener switch harness connector.

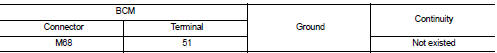

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair harness or connector.

3.CHECK BACK DOOR REQUEST SWITCH GROUND CIRCUIT

Check continuity between back door opener switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK BACK DOOR REQUEST SWITCH

Refer to DLK-72, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace back door opener switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK BACK DOOR REQUEST SWITCH

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

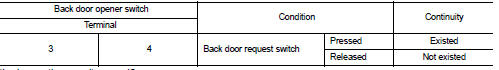

3. Check continuity between back door opener switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace back door opener switch.

Back door opener switch

Back door opener switch

Component Function Check

1.CHECK FUNCTION

1. Select “TRUNK” of “BCM” using CONSULT-III.

2. Select “TR/BD OPEN SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to ...

Buzzer (combination meter)

Buzzer (combination meter)

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “INSIDE BUZZER” in “ACTIVE TEST” mode.

3. Check that the function operates normally acco ...

Other materials:

Fuel gauge

The gauge1 indicates the approximate fuel level in the tank.

The gauge may move slightly during braking, turning, acceleration, or going up

or down hills.

Refill the fuel tank before the gauge registers 0 (empty). The low fuel

warning light illuminates when the

amount of fuel in the tank ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Horn function

Component Function Check

1.CHECK FUNCTION 1

1. Disconnect vehicle security horn relay.

2. Perform “VEHICLE SECURITY HORN” in “ACTIVE TEST” mode of “THEFT ALM” of “BCM”

using CONSULT-

III.

3. Check the horn operation.

Is the operation normal?

YES >> GO TO 2.

NO >> Go to SEC- ...