Nissan Juke Service and Repair Manual : Back door opener switch

Component Function Check

1.CHECK FUNCTION

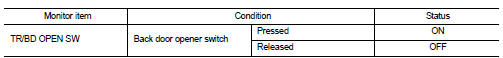

1. Select “TRUNK” of “BCM” using CONSULT-III.

2. Select “TR/BD OPEN SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Back door opener switch is OK.

NO >> Refer to DLK-69, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BACK DOOR OPENER SWITCH INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

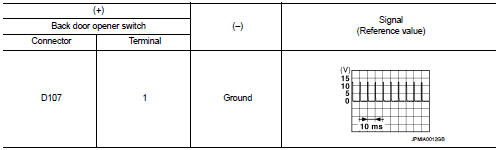

3. Check signal between back door opener switch harness connector and ground using oscilloscope.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK BACK DOOR OPENER SWITCH CIRCUIT

1. Disconnect BCM connector.

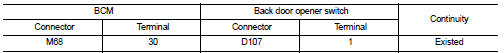

2. Check continuity between BCM harness connector and back door opener switch harness connector.

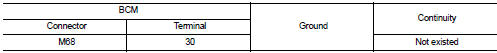

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-93, "Removal and Installation".

NO >> Repair or replace harness.

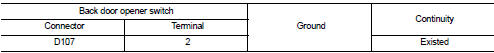

3.CHECK BACK DOOR OPENER SWITCH GROUND CIRCUIT

Check continuity between back door opener switch harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace harness.

4.CHECK BACK DOOR OPENER SWITCH

Refer to DLK-70, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace back door opener switch.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

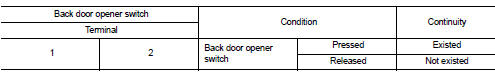

1.CHECK BACK DOOR OPENER SWITCH

1. Turn ignition switch OFF.

2. Disconnect back door opener switch connector.

3. Check continuity between back door opener switch terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace back door opener switch.

Back door opener actuator

Back door opener actuator

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “TRUNK/BACK DOOR” in “ACTIVE TEST” mode.

3. Check that the function operates normally ac ...

Back door request switch

Back door request switch

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-BD/TR” in “DATA MONITOR” mode.

3. Check that the function operates normally acco ...

Other materials:

Door motor starting position reset

Description

• Reset signal is transmitted from A/C auto amp. to air mix door motor and

mode door motor. Starting position

reset can be performed.

NOTE:

During reset, DEF switch indicator blinks.

• When air mix door motor or mode door motor is removed and installed, always

perform door m ...

Antenna

To remove the antenna, hold the bottom of the antenna and turn it counterclockwise.

To install the antenna, turn the antenna clockwise and tighten.

CAUTION

• To avoid damaging or deforming the antenna, be sure to fold down (if so

equipped) or remove the antenna under the following conditions. ...

Headlamp washer circuit

Component Function Check

1.CHECK HEADLAMP WASHER OPERATION

CONSULT-III ACTIVE TEST

1. Select “HEAD LAMP WASHER” of IPDM E/R active test item.

2. With operating the test item, check headlamp operation.

On :Headlamp washer ON operation

Off :Stop the headlamp washer.

Is headlamp washer operation ...