Nissan Juke Service and Repair Manual : P0524 engine oil pressure

DTC Logic

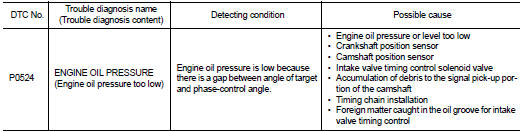

DTC DETECTION LOGIC

NOTE

:

If DTC P0524 is displayed with DTC P0520, P0075, or P0081, perform trouble

diagnosis for DTC P0520,

P0075, or P0081 first. Refer to EC-176, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is

between 10 V and 16 V at

idle.

>> GO TO 2.

2.PRECONDITIONING-II

Check oil level and oil pressure. Refer to LU-8, "Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Proceed to LU-8, "Inspection".

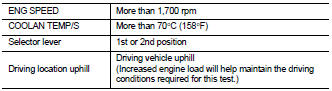

3.PERFORM DTC CONFIRMATION PROCEDURE

WITH CONSULT-III

WITH CONSULT-III

1. Select “DATA MONITOR” mode of “ENGINE” using CONSULT-III.

2. Maintain the following conditions for at least 20 consecutive seconds.

CAUTION:

Always drive at a safe speed.

3. Check 1st trip DTC.

WITH GST

WITH GST

Follow the procedure “With CONSULT-III” above.

Is 1st trip DTC detected? YES >> Proceed to EC-298, "Diagnosis Procedure" NO >> INSPECTION END

Diagnosis Procedure

1.CHECK OIL PRESSURE WARNING LAMP

1. Start engine.

2. Check oil pressure warning lamp and confirm it is not illuminated.

Is oil pressure warning lamp illuminated? YES >> Proceed to MWI-66, "Diagnosis Procedure".

NO >> GO TO 2.

2.CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

Refer to EC-164, "Component Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Replace malfunctioning intake valve timing control solenoid valve. Refer to EM-67, "Exploded View".

3.CHECK CRANKSHAFT POSITION SENSOR

Refer to EC-273, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace crankshaft position sensor. Refer to EM-78, "Exploded View".

4.CHECK CAMSHAFT POSITION SENSOR

Refer to EC-276, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace malfunctioning camshaft position sensor. Refer to EM-78, "Exploded View".

5.CHECK CAMSHAFT (INT)

Check the following.

• Accumulation of debris to the signal plate of camshaft rear end • Chipping signal plate of camshaft rear end

Is the inspection result normal? YES >> GO TO 6.

NO >> Remove debris and clean the signal plate of camshaft rear end or replace camshaft. Refer to EM-79, "Removal and Installation".

6.CHECK TIMING CHAIN INSTALLATION

Check service records for any recent repairs that may cause timing chain misaligned.

Are there any service records that may cause timing chain misaligned? YES >> Check timing chain installation. Refer to EM-67, "Exploded View".

NO >> GO TO 7.

7.CHECK LUBRICATION CIRCUIT

Perform “Inspection of Camshaft Sprocket (INT) Oil Groove”. Refer to EM-82, "Inspection".

Is the inspection result normal? YES >> Check intermittent incident. refer to GI-42, "Intermittent Incident".

NO >> Clean lubrication line.

P0520 EOP sensor

P0520 EOP sensor

DTC Logic

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. ...

P0603 ECM power supply

P0603 ECM power supply

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

Cylinder block

Exploded View

1. Cylinder block

2. Top ring

3. Second ring

4. Oil ring

5. Piston

6. Piston pin

7. Snap ring

8. Connecting rod

9. Connecting rod bearing (upper)

10. Connecting rod bearing (lower)

11. Crankshaft key

12. Connecting rod cap

13. Connecting rod cap bolt

14. Main ...

ASCD indicator

Component Function Check

1.CHECK ASCD INDICATOR FUNCTION

Check ASCD indicator under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-767, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK DTC

Check that DTC UXXXX is not ...

Symptom diagnosis

Noise, vibration and harshness

(NVH) Troubleshooting

NVH troubleshooting Chart

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

A: Closely rel ...