Nissan Juke Service and Repair Manual : P0520 EOP sensor

DTC Logic

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-293, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ENGINE OIL

1. Turn ignition switch OFF.

2. Check engine oil level and pressure. Refer to LU-8, "Inspection".

Is inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

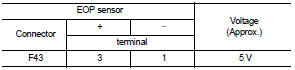

2.CHECK EOP SENSOR POWER SUPPLY-I

1. Disconnect EOP sensor connector.

2. Turn ignition switch ON.

3. Check the voltage between EOP sensor harness connector terminals.

Inspection result normal? YES >> GO TO 7.

NO >> GO TO 3.

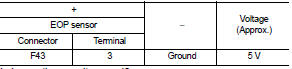

3.CHECK EOP SENSOR POWER SUPPLY-II

Check the voltage between EOP sensor harness connector and the ground.

Is inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

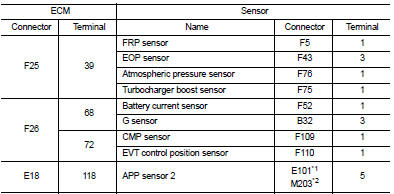

4.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

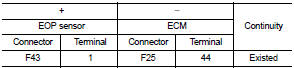

5.CHECK EOP SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOP sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

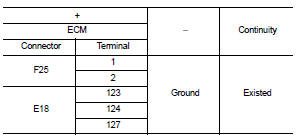

6.CHECK ECM GROUND CIRCUIT

Check the continuity between ECM harness connector and ground.

Is inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

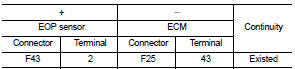

7.CHECK EOP SENSOR SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EOP sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and to power.

Is inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK EOP SENSOR

Refer to EC-296, "Component Inspection".

Is inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Repair or replace error-detected parts.

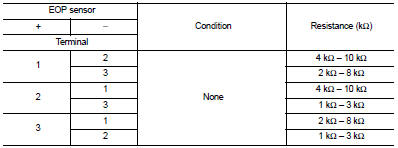

Component Inspection

1.CHECK EOP SENSOR

1. Turn ignition switch OFF.

2. Disconnect EOP sensor harness connector.

3. Check resistance between EOP sensor connector terminals.

Is the inspection result normal? YES >> INSPECTION END.

NO >> Replace EOP sensor. Refer to EM-103, "Exploded View".

P0507 ISC system

P0507 ISC system

Description

The ECM controls the engine idle speed to a specified level through the fine

adjustment of the air, which is let

into the intake manifold, by operating the electric throttle control ac ...

P0524 engine oil pressure

P0524 engine oil pressure

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0524 is displayed with DTC P0520, P0075, or P0081, perform trouble

diagnosis for DTC P0520,

P0075, or P0081 first. Refer to EC-176, "DTC Logic&qu ...

Other materials:

Removal and Installation

CAUTION:

• Be sure to use genuine exhaust system parts or equivalents which are specially

designed for heat

resistance, corrosion resistance and shape.

• Perform the operation with the exhaust system fully cooled down because the

system is still hot just

after the engine stops.

• Be careful ...

Back door does not opened

Diagnosis Procedure

1.CHECK BACK DOOR OPENER SWITCH

Check back door opener switch.

Refer to DLK-384, "Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK BACK DOOR OPENER ACTUATOR

...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...