Nissan Juke Service and Repair Manual : P0335 CKP sensor (POS)

DTC Logic

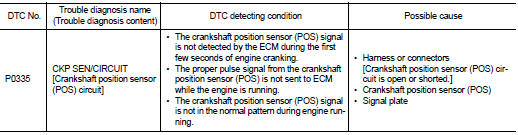

DTC DETECTION LOGIC

NOTE

:

If DTC P0340 is displayed with DTC P0643, first perform the trouble diagnosis

for DTC P0643.

Refer to EC-307, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10.5 V with ignition

switch ON.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for at least 5 seconds.

If engine does not start, crank engine for at least 2 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-271, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

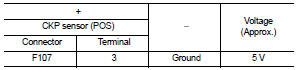

1.CHECK CRANKSHAFT POSITION (CKP) SENSOR (POS) POWER SUPPLY

1. Disconnect crankshaft position (CKP) sensor (POS) harness connector.

2. Turn ignition switch ON.

3. Check the voltage between CKP sensor (POS) harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

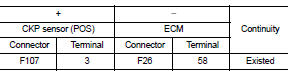

2.CHECK CKP SENSOR (POS) POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF 2. Disconnect ECM harness connector.

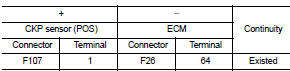

3. Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

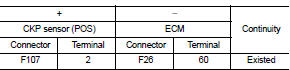

3.CHECK CKP SENSOR (POS) GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK CKP SENSOR (POS) INPUT SIGNAL CIRCUIT

1. Check the continuity between CKP sensor (POS) harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK CRANKSHAFT POSITION SENSOR (POS)

Check the crankshaft position sensor (POS). Refer to EC-273, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace crankshaft position sensor (POS). Refer to EM-103, "Exploded View".

6.CHECK GEAR TOOTH

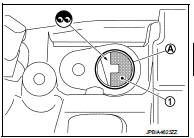

1. Remove crankshaft position sensor (POS). Refer to EM-103, "Exploded View".

2. Look into the mounting hole (A) of the crankshaft position sensor (POS) to check that there is no missing gear tooth in the signal plate (1).

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace the signal plate. Refer to EM-103, "Exploded View".

Component Inspection

1.CHECK CRANKSHAFT POSITION SENSOR (POS)-I

1. Turn ignition switch OFF.

2. Loosen the fixing bolt of the sensor.

3. Disconnect crankshaft position sensor (POS) harness connector.

4. Remove the sensor.

5. Visually check the sensor for chipping.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace crankshaft position sensor (POS). Refer to EM- 103, "Exploded View".

2.CHECK CRANKSHAFT POSITION SENSOR (POS)-II

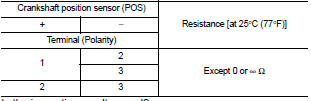

Check the resistance between crankshaft position sensor (POS) terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END NO >> Replace crankshaft position sensor (POS). Refer to EM-103, "Exploded View".

P0327, P0328 KS

P0327, P0328 KS

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P0340 CMP sensor (PHASE)

P0340 CMP sensor (PHASE)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

P012A TC boost sensor

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTIONS

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or ...

P060B ECM

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.INSPECTION START

1. Turn ignition switch ON.

2. Erase DTC.

3. Turn ignition switch OFF and wait for 20 seconds.

4. Turn ignition switch ON and perform the self-diagnosis.

Is the DTC P060B displayed again?

YES >> GO TO 2.

NO &g ...

P0133 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction of A/F sensor 1, this diagnosis measures response

time of the A/F signal computed

by ECM from the A/F sensor 1 signal. The time is compensated by engine operating

(speed and load), fuel

feedback control constant, and the A/F sensor 1 tem ...