Nissan Juke Service and Repair Manual : P0327, P0328 KS

DTC Logic

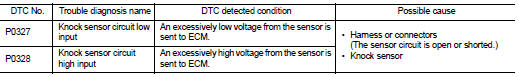

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 10 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Go to EC-654, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedur

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

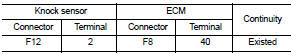

2.CHECK KNOCK SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Disconnect knock sensor harness connector.

2. Disconnect ECM harness connector.

3. Check the continuity between knock sensor harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

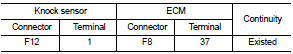

3.CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check the continuity between knock sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK KNOCK SENSOR

Refer to EC-655, "Component Inspection".

Is the inspection result normal? YES >> GO TO 5.

NO >> Replace knock sensor.

5.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK KNOCK SENSOR

1. Turn ignition switch OFF.

2. Disconnect knock sensor harness connector.

3. Check resistance between knock sensor terminals as follows.

NOTE: It is necessary to use an ohmmeter which can measure more than 10 MΩ.

CAUTION:

Do not use any knock sensors that have been dropped or physically damaged. Use

only new ones.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace knock sensor.

P0300, P0301, P0302, P0303, P0304 misfire

P0300, P0301, P0302, P0303, P0304 misfire

DTC Logic

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, ECM can ...

P0335 CKP sensor (POS)

P0335 CKP sensor (POS)

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always turn

ignition switch OFF and wait at

least 10 se ...

Other materials:

Park/neutral position (PNP) switch : Component Inspection

1.CHECK PARK/NEUTRAL POSITION (PNP) SWITCH

1. Disconnect position switch connector. Refer to TM-77, "Removal and

Installation".

2. Check continuity between position switch terminals.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace position switch ...

Trouble diagnosis - specification

value

Description

The specification (SP) value indicates the tolerance of the value that is

displayed in “SPEC” of “DATA MONITOR”

mode of CONSULT-III during normal operation of the Engine Control System. When

the value in “SPEC”

of “DATA MONITOR” mode is within the SP value, the Engine Control Sys ...

Precaution for Brake Control system

• Always perform a pre-driving check to drive the vehicle.

• Always check speed and safety while driving the vehicle.

• To operate CONSULT-III while driving, more than one person is required to be

in the vehicle to avoid interference

to driving and ensure safety.

• Slight vibrations are felt o ...