Nissan Juke Service and Repair Manual : P0237, P0238 TC boost sensor

DTC Logic

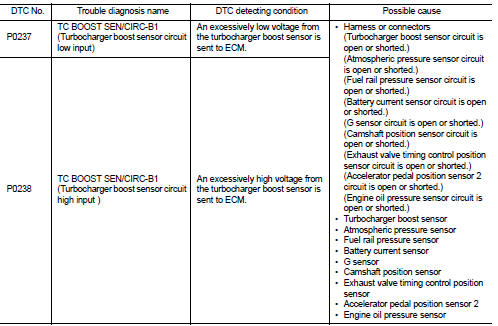

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-260, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

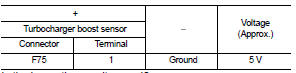

1.CHECK TURBOCHARGER BOOST SENSOR POWER SUPPLY

1. Disconnect turbocharger boost sensor harness connector.

2. Turn ignition switch ON.

3. Check the voltage between turbocharger boost sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

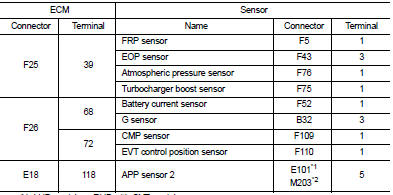

2.CHECK SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness connector for short to power and short to ground, between the following terminals.

*1: LHD models or RHD with CVT models *2: RHD with M/T models

Is inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

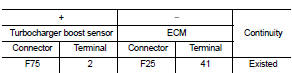

3.CHECK TURBOCHARGER BOOST SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between turbocharger boost sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK TURBOCHARGER BOOST SENSOR INPUT SIGNAL CIRCUIT

1. Check the continuity between turbocharger boost sensor harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK TURBOCHARGER BOOST SENSOR

Check the turbocharger boost sensor. Refer to EC-262, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace turbocharger boost sensor. Refer to EM-36, "Exploded View".

Component Inspection

1.CHECK TURBOCHARGER BOOST SENSOR

1. Turn ignition switch OFF.

2. Remove turbocharger boost sensor with its harness connector.

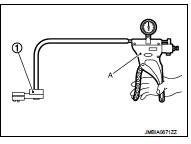

3. Install pressure pump (A) to turbocharger boost sensor (1).

CAUTION:

When insert a pressure pump hose to the sensor, be careful

to the damage of the sensor housing.

4. Turn ignition switch ON.

5. Check the voltage between ECM harness connector terminals as per the following conditions.

NOTE

:

• Always calibrate the pressure pump gauge when using it.

• Inspection should be done at room temperature [10 - 30°C (50 - 86°F)].

Is the inspection result normal? YES >> INSPECTION END NO >> Replace turbocharger boost sensor. Refer to EM-36, "Exploded View".

P0234 TC system

P0234 TC system

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0234 is displayed with DTC P0237 or P0238, first perform the trouble

diagnosis for DTC P0237 or

P0238. Refer to EC-260, "DTC Logic".

DTC ...

P0300, P0301, P0302, P0303, P0304 misfire

P0300, P0301, P0302, P0303, P0304 misfire

DTC Logic

DTC DETECTION LOGIC

When a misfire occurs, engine speed will fluctuate. If the engine speed

fluctuates enough to cause the crankshaft

position (CKP) sensor (POS) signal to vary, ECM can ...

Other materials:

Driver side door mirror defogger

Description

Heats the heating wire with the power supply from the rear window defogger

relay to prevent the door mirror

from fogging up.

Component Function Check

1.CHECK DRIVER SIDE DOOR MIRROR DEFOGGER

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. C ...

C1140 actuator relay system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication system for real time

application. It is an on-vehicle

multiplex communication system with high data communication speed and excellent

error detectability. Many

electronic control units are equipped onto vehicles, and each con ...