Nissan Juke Service and Repair Manual : P0234 TC system

DTC Logic

DTC DETECTION LOGIC

NOTE

:

If DTC P0234 is displayed with DTC P0237 or P0238, first perform the trouble

diagnosis for DTC P0237 or

P0238. Refer to EC-260, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to EC-257, "Component Function Check".

NOTE

:

Use component function check to check the overall function of the turbocharger

system circuit. During this

check, DTC might not be confirmed.

Is the inspection result normal? YES >> INSPECTION END NO >> Proceed to EC-258, "Diagnosis Procedure".

Component Function Check

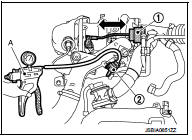

1.CHECK BOOST CONTROL ACTUATOR HOSE

Check disconnection, looseness or improper connection of hose between turbocharger boost control solenoid valve and boost control actuator.

Is the inspection result normal? YES >> GO TO 2.

NO >> Proceed to EC-258, "Diagnosis Procedure".

2.PERFORM COMPONENT FUNCTION CHECK

1. Turn ignition switch OFF.

2. Disconnect turbocharger boost control solenoid valve harness connector.

3. Disconnect of hose between turbocharger boost control solenoid valve and compressor wheel.

4. Install pressure pump to turbocharger boost control solenoid valve.

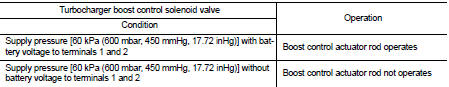

5. Check that the rod of the boost control actuator activates when supplying pressure and battery voltage to the turbocharger boost control solenoid valve as per the following conditions

CAUTION:

Do not supply pressure over 70 kPa (700 mbar, 525 mmHg, 20.67 inHg)

Is the inspection result normal? YES >> INSPECTION END

NO >> Proceed to EC-258, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK BOOST CONTROL ACTUATOR HOSE

Check disconnection, looseness or improper connection of hose between turbocharger boost control solenoid valve and boost control actuator.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

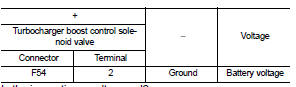

2.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect turbocharger boost control solenoid valve harness connector.

3. Turn ignition switch ON.

4. Check the voltage between turbocharger boost control solenoid valve harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

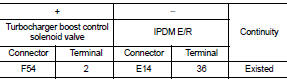

3.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between turbocharger boost control solenoid valve harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

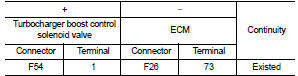

4.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between turbocharger boost control solenoid valve harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK TURBOCHARGER BOOST CONTROL SOLENOID VALVE

Check the turbocharger boost control solenoid valve. Refer to EC-175, "Component Inspection".

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace turbocharger boost control solenoid valve. Refer to EM-36, "Exploded View".

6.CHECK BOOST CONTROL ACTUATOR

Check the boost control actuator. Refer to EM-37, "Inspection".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace exhaust manifold and turbocharger assembly. Refer to EM-36, "Exploded View".

7.CHECK TURBOCHARGER BOOST SENSOR

Check the turbocharger boost sensor. Refer to EC-262, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace turbocharger boost sensor. Refer to EM-31, "Exploded View".

P0222, P0223 TP sensor

P0222, P0223 TP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0222 or P0223 is displayed with DTC P0643 ,first perform the trouble

diagnosis for DTC P0643.

Refer to EC-274, "DTC Logic".

DTC CONFIRM ...

P0237, P0238 TC boost sensor

P0237, P0238 TC boost sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Door mirror defogger

Description

Heats the heating wire with the power supply from the rear window defogger

relay to prevent the door mirror

from fogging up.

Component Function Check

1.CHECK DOOR MIRROR DEFOGGER

1. Perform IPDM E/R Active Test (“REAR DEFOGGER”) using CONSULT-III.

2. Touch “ON”.

3. Check that bo ...

P1864 input speed signal

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.DTC REPRODUCTION PROCEDURE

With ...