Nissan Juke Service and Repair Manual : P0112, P0113 IAT sensor

DTC Logic

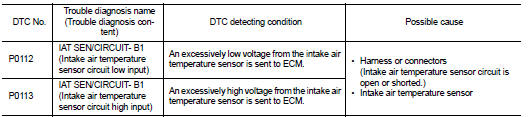

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-198, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

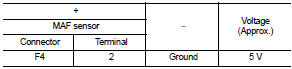

1.CHECK INTAKE AIR TEMPERATURE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect mass air flow sensor (with intake air temperature sensor) harness connector.

3. Turn ignition switch ON.

4. Check the voltage between mass air flow sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

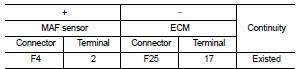

2.CHECK INTAKE AIR TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between mass air flow sensor harness connector and ECM harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

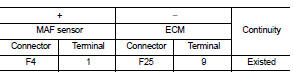

3.CHECK INTAKE AIR TEMPERATURE SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between mass air flow sensor harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK INTAKE AIR TEMPERATURE SENSOR

Check the intake air temperature sensor. Refer to EC-199, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace mass air flow sensor (with intake air temperature sensor). Refer to EM-26, "Exploded View".

Component Inspection

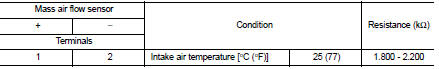

1.CHECK INTAKE AIR TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect mass air flow sensor harness connector.

3. Check resistance between mass air flow sensor terminals as per the following.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace mass air flow sensor (with intake air temperature sensor). Refer to EM-26, "Exploded View".

P0107, P0108 atmospheric pressure

sensor

P0107, P0108 atmospheric pressure

sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducti ...

P0117, P0118 ECT sensor

P0117, P0118 ECT sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

Gas station information

FUEL RECOMMENDATION:

NISSAN recommends the use of unleaded premium gasoline with an octane rating

of at least 91 AKI (Anti-Knock Index) number (Research octane number 96).

If unleaded premium gasoline is not available, you may use unleaded regular gasoline

with an octane rating of at least 87 ...

Structure and operation

Sectional View

1. Transfer cover

2. Ring gear shaft

3. Companion flange

4. Drive pinion

5. Ring gear

6. Transfer case

Operation Principle

POWER TRANSFER DIAGRAM

1. Engine

2. Transaxle

3. Transfer

4. Propeller shaft

5. Electric controlled coupling

6. Rear final drive

ELECTR ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...