Nissan Juke Service and Repair Manual : P0117, P0118 ECT sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn ignition switch ON and wait at least 5 seconds.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-200, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

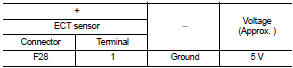

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect engine coolant temperature (ECT) sensor harness connector.

3. Turn ignition switch ON.

4. Check the voltage between ECT sensor harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

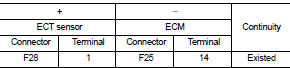

2.CHECK ENGINE COOLANT TEMPERATURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between ECT sensor harness connector and ECM harness connector.

4. Also check harness for short to ground.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

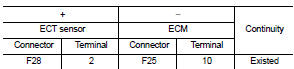

3.CHECK ENGINE COOLANT TEMPERATURE SENSOR GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between ECT sensor harness connector and ECM harness connector.

4. Also check harness for short to ground to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK ENGINE COOLANT TEMPERATURE SENSOR

Check the engine coolant temperature sensor. Refer to EC-201, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace engine coolant temperature sensor. Refer to EM-90, "Exploded View".

Component Inspection

1.CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Turn ignition switch OFF.

2. Disconnect engine coolant temperature sensor harness connector.

3. Remove engine coolant temperature sensor.

4. Check resistance between engine coolant temperature sensor terminals by heating with hot water as shown in the figure.

Is the inspection result normal? YES >> INSPECTION END NO >> Replace engine coolant temperature sensor. Refer to EM-90, "Exploded View".

P0112, P0113 IAT sensor

P0112, P0113 IAT sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P0122, P0123 TP sensor

P0122, P0123 TP sensor

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0122 or P0123 is displayed with DTC P0643, first perform the trouble

diagnosis for DTC P0643.

Refer to EC-307, "DTC Logic".

DTC CONFIRM ...

Other materials:

Precaution for Brake System

WARNING:

Clean any dust from the front brake and rear brake with a vacuum dust collector.

Never blow with compressed

air.

• Brake fluid use refer to MA-13, "Fluids and Lubricants".

• Never reuse drained brake fluid.

• Never spill or splash brake fluid on painted surfaces. Brake flui ...

B1210 side collision detection

Description

The side air bag and curtain air bag are activated by the air bag diagnosis

sensor unit signal transmitted at the

time of side collision.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform ...

Diagnosis system (BCM) (with intelligent key system)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...