Nissan Juke Service and Repair Manual : P0122, P0123 TP sensor

DTC Logic

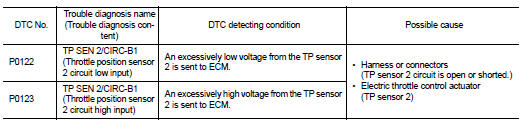

DTC DETECTION LOGIC

NOTE

:

If DTC P0122 or P0123 is displayed with DTC P0643, first perform the trouble

diagnosis for DTC P0643.

Refer to EC-307, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more

than 8 V at idle.

>> GO TO 2.

2.PERFORM DTC CONFIRMATION PROCEDURE

1. Start engine and let it idle for 1 second.

2. Check DTC.

Is DTC detected? YES >> Proceed to EC-202, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

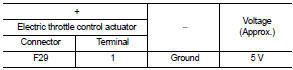

1.CHECK THROTTLE POSITION SENSOR 2 POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect electric throttle control actuator harness connector.

3. Turn ignition switch ON.

4. Check the voltage between electric throttle control actuator harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

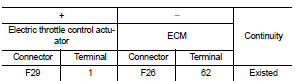

2.CHECK THROTTLE POSITION SENSOR 2 GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

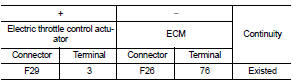

3. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

4. Also check harness for short to power.

Is the inspection result normal? YES >> Perform the trouble diagnosis for power supply circuit.

NO >> Repair or replace error-detected parts.

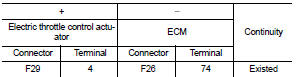

3.CHECK THROTTLE POSITION SENSOR 2 GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK THROTTLE POSITION SENSOR 2 INPUT SIGNAL CIRCUIT

1. Check the continuity between electric throttle control actuator harness connector and ECM harness connector.

2. Also check harness for short to ground and to power.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

5.CHECK THROTTLE POSITION SENSOR

Check the throttle position sensor. Refer to EC-203, "Component Inspection".

Is the inspection result normal? YES >> Check intermittent incident. Refer to GI-42, "Intermittent Incident".

NO >> Replace electric throttle control actuator. Refer to EM-28, "Exploded View".

Component Inspection

1.CHECK THROTTLE POSITION SENSOR

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Perform “ Throttle Valve Closed Position Learning”. Refer to EC-135, "Work Procedure".

4. Turn ignition switch ON.

5. Set selector lever to D (CVT) or 1st (M/T) position.

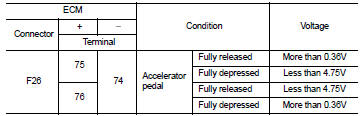

6. Check the voltage between ECM harness connector terminals as per the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace electric throttle control actuator. Refer to EM-28, "Exploded View".

P0117, P0118 ECT sensor

P0117, P0118 ECT sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P0130 A/F sensor 1

P0130 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal fluctuates according to fuel feedback control.

DTC ...

Other materials:

Intelligent Keys (if so equipped)

Your vehicle can only be driven with the Intelligent Keys which are registered

to your vehicle’s Intelligent Key system components and NISSAN Vehicle Immobilizer

System components.

As many as 4 Intelligent Keys can be registered and used with one vehicle. The

new keys must be registered by a ...

Information display (speed limiter)

Component Function Check

1.CHECK INFORMATION DISPLAY (SPEED LIMITER) FUNCTION

1. Start engine.

2. Press speed limiter MAIN switch.

3. Drive the vehicle at more than 30 km/h (20 MPH).

CAUTION:

Always drive vehicle at a safe speed.

4. Press SET/COAST switch.

5. Perform a test drive on a flat ...

B1215, B1216, B1217 satellite sensor LH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...