Nissan Juke Service and Repair Manual : P0087, P0088, P0090 FRP control system

DTC Logic

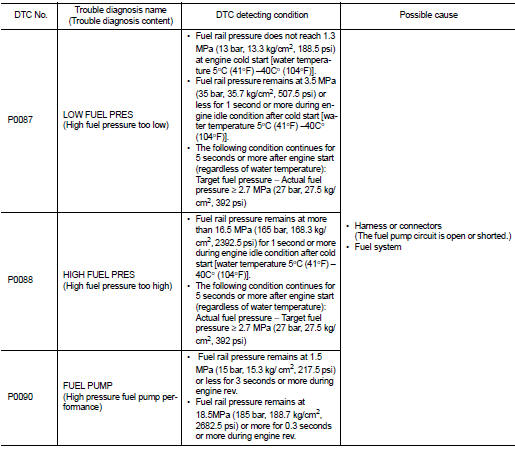

DTC DETECTION LOGIC

NOTE

:

• If DTC P0087 or P0090 is displayed with DTC P1197, first perform the trouble

diagnosis for DTC

P1197.

• DTC P0087 or P0090 may be displayed when running out of gas.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform the following procedure before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition switch ON.

3. Turn ignition switch OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is 11 V

or more at idle.

2.PERFORM DTC CONFIRMATION PROCEDURE-I

1. Check that the fuel tank is 1/8 full of fuel.

2. Warm up the engine to the normal operating temperature and keep the engine speed at idle for 10 seconds.

NOTE

:

Warm up the engine until “COOLAN TEMP/S” on “DATA MONITOR” mode of “ENGINE”

using CONSULTIII

reaches at least 70°C (158°F).

3. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-183, "Diagnosis Procedure".

NO >> GO TO 3.

3.PERFORM DTC CONFIRMATION PROCEDURE-II

1. Cool the engine until the engine coolant temperature reaches 60°C (140°F) or less.

2. Start the engine and wait at least 40 seconds.

3. Check 1st trip DTC.

Is 1st trip DTC detected? YES >> Proceed to EC-183, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.PERFORM THE HIGH PRESSURE FUEL PUMP COMPONENT INSPECTION

Perform the high pressure fuel pump component inspection. Refer to EC-183, "Component Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace the fuel pump. FL-6, "2WD : Exploded View" (2WD) or FL-10, "4WD : Exploded View" (4WD).

2.CHECK FUEL LEAKAGE

1. Start the engine.

2. Visually check that the fuel pump, fuel rail, and fuel piping have no fuel leakage.

Is the inspection result normal? YES >> Check that the fuel system has no breakage, bend, and crush. Refer to FL-5, "Inspection".

NO >> Repair or Replace the error-detected parts.

Component Inspection

1.CHECK HIGH PRESSURE FUEL PUMP-I

1. Turn ignition switch OFF.

2. Disconnect high pressure fuel pump harness connector.

3. Check the resistance between high pressure fuel pump terminals as follows.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace high pressure fuel pump. Refer to EM-43, "Exploded View".

2.CHECK HIGH PRESSURE FUEL PUMP-II

With CONSULT-III

With CONSULT-III

1. Reconnect high pressure fuel pump harness connector.

2. Start the engine.

3. Check “FUEL PRES SEN” in “DATA MONITOR” of “ENGINE” using CONSULT-III.

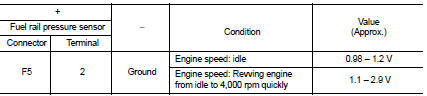

Without CONSULT-III

Without CONSULT-III

1. Start the engine.

2. Check fuel rail pressure sensor signal voltage.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace high pressure fuel pump. Refer to EM-43, "Exploded View".

P0078 EVT control solenoid valve

P0078 EVT control solenoid valve

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

P0097, P0098 IAT sensor 2

P0097, P0098 IAT sensor 2

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conductin ...

Other materials:

Vacuum pump

Exploded View

1. Vacuum pump

2. Gasket

3. Damper valve bracket

4. Vacuum hose

A. To electric throttle control actuator

Engine front

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-280, "Expl ...

P1726 throttle control signal

Description

Electric throttle control actuator consists of throttle control motor,

accelerator pedal position sensor, throttle

position sensor etc. The actuator sends a signal to the ECM, and ECM sends the

signal to TCM with CAN

communication.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATI ...

B26E8 clutch interlock switch

DTC Logic

NOTE:

• If DTC B26E8 is displayed with DTC B210F, first perform the trouble diagnosis

for DTC B210F. Refer to

BCS-83, "DTC Logic".

• If DTC B26E8 is displayed with DTC B2110, first perform the trouble diagnosis

for DTC B2110. Refer to

BCS-84, "DTC Logic".

DT ...