Nissan Juke Service and Repair Manual : Key interlock cable

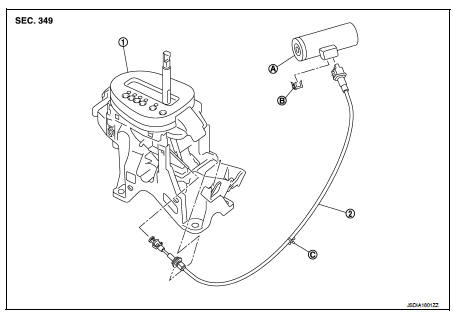

Exploded View

1. CVT shift selector assembly 2. Key interlock cable

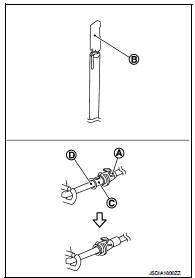

A: Key cylinder

B: Clip

C: Clip

Removal and Installation

REMOVAL

CAUTION:

Always apply the parking brake before performing removal and installation.

1. Shift the selector lever to the “P” position.

2. Remove the selector lever knob. Refer to TM-271, "Disassembly and Assembly".

3. Remove the center console. Refer to IP-23, "Removal and Installation".

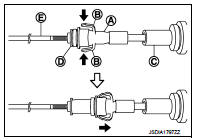

4. Press the pawls (B) of the key interlock cable slider (A) while sliding it in the direction of the casing cap (C), and separate the adjusting holder (D) and slider

E :Key interlock rod

5. Remove the key interlock cable from the CVT shift selector.

6. Remove the steering column lower cover and driver instrument lower panel. Refer to IP-13, "Removal and Installation".

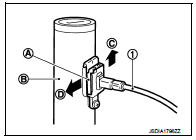

7. Lift clip (A) in the direction of the arrow (

C) and remove in the

C) and remove in the

direction of the arrow (  D).

D).

1 :Key interlock cable B :Key cylinder

8. Disconnect the key interlock cable from the key cylinder.

9. Disengage the clip and disconnect the key interlock cable from the vehicle

INSTALLATION

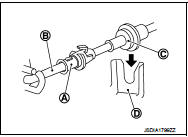

• Install the adjusting holder (A) onto the key interlock rod (B), then install the casing cap (C) onto the CVT shift selector cable bracket (D).

CAUTION:

• When installing the key interlock cable, never bend or twist

the cable forcefully.

• After connecting the key interlock cable to the CVT shift selector cable bracket, be sure to check that the casing cap is completely fastened to the cable bracket. If the casing cap is easily displaced, replace the key interlock cable.

• While pressing the detent rod (B) down, slide the key interlock cable slider (A) toward the key interlock rod (D) side, and install the adjusting holder (C) and key interlock rod.

CAUTION:

• Never squeeze the pawls on the key interlock cable slider

when holding the slider.

• Never apply force in a perpendicular direction to the key interlock rod when sliding the slider.

Inspection

INSPECTION AFTER INSTALLATION

• Check the CVT position. If a malfunction is found, adjust the CVT position. Refer to TM-194, "Inspection and Adjustment".

• The key can be removed only when the selector lever is in the “P” position.

• It must not be possible to turn the ignition switch to LOCK when the selector lever is not in the “P” position.

Control cable

Control cable

Exploded View

1. Control cable

2. Lock plate

3. Transaxle assembly

4. Bracket A

5. Bracket B

6. CVT shift selector assembly

A: Manual lever B: Grommet

: N·m (kg-m, ft-lb)

: N·m (kg-m, i ...

Transmission range switch

Transmission range switch

Exploded View

1. Transmission range switch

2. Transaxle assem

Removal and Installation

REMOVAL

1. Remove battery. Refer to PG-124, "Removal and Installation".

2. Remove transmission ...

Other materials:

Hood

WARNING

• Make sure the hood is completely closed and latched before driving.

Failure to do so could cause the hood to fly open and result in an accident.

• If you see steam or smoke coming from the engine compartment, to avoid injury

do not open the hood.

When opening the hood:

1. Pull the ...

P1705 TP sensor

Description

Electric throttle control actuator consists of throttle control motor,

accelerator pedal position sensor, throttle

position sensor etc. The actuator sends a signal to the ECM, and ECM sends the

signal to TCM with CAN

communication.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATI ...

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...