Nissan Juke Service and Repair Manual : C1113, C1145, C1146 yaw rate/side/decel g sensor

DTC Logic

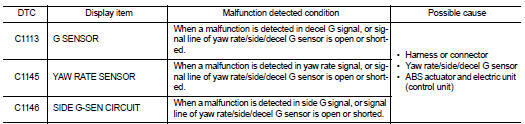

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ABS”.

Is DTC “C1113” “C1145” or “C1146” detected? YES >> Proceed to BRC-165, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY SYSTEM

Check ABS actuator and electric unit (control unit) power supply system. Refer to BRC-205, "Diagnosis Procedure".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace error-detected parts.

2.CHECK CONNECTOR

1. Turn ignition switch OFF.

2. Check ABS actuator and electric unit (control unit) harness connector for disconnection or looseness.

3. Check yaw rate/side/decel G sensor harness connector for disconnection or looseness.

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts, securely lock the connector, and GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis for “ABS” again.

Is DTC“C1113”, “C1145” or “C1146” detected? YES >> GO TO 4.

NO >> INSPECTION END

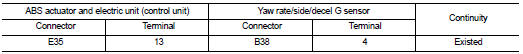

4.CHECK YAW RATE/SIDE/DECEL G SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Disconnect yaw rate/side/decel G sensor harness connector.

4. Check continuity between yaw rate/side/decel G sensor harness connector and ABS actuator and electric unit (control unit) harness connector.

Is the inspection result normal? YES >> GO TO 5.

NO >> Repair or replace error-detected parts.

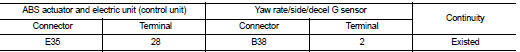

5.CHECK YAW RATE/SIDE/DECEL G SENSOR GROUND SIRCUIT

Check continuity between yaw rate/side/decel G sensor harness connector and ABS actuator and electric unit (control unit) harness connector.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair or replace error-detected parts.

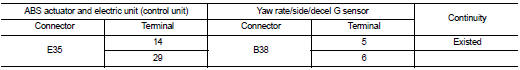

6.CHECK YAW RATE/SIDE/DECEL G SENSOR SIGNAL CIRCUIT

Check continuity between yaw rate/side/decel G sensor harness connector and ABS actuator and electric unit (control unit) harness connector.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts.

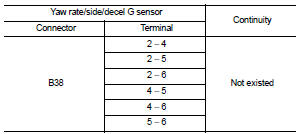

7.CHECK YAW RATE/SIDE/DECEL G SENSOR CIRCUIT

Check continuity between each terminals of yaw rate/side/decel G sensor harness connector.

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts.

8.CHECK YAW RATE/SIDE/DECEL G SENSOR 1

With CONSULT-III.

With CONSULT-III.

1. Connect yaw rate/side/decel G sensor harness connector.

2. Connect ABS actuator and electric unit (control unit) harness connector.

3. Turn the ignition switch ON.

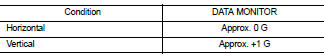

4. Select “ABS”, “DATA MONITOR” and “DECEL G-SEN” in order.

5. Move yaw rate/side/decel G sensor as shown in the figure to check the output of before and after moving the sensor.

Is the inspection result normal? YES >> GO TO 9.

NO >> Replace yaw rate/side/decel G sensor. Refer to BRC- 235, "Removal and Installation".

9.CHECK YAW RATE/SIDE/DECEL G SENSOR 2

1. Turn ignition switch OFF.

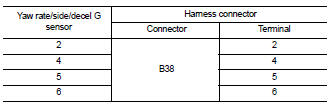

2. Connect following terminals between yaw rate/side/decel G sensor and harness connector.

3. Turn ignition switch ON.

CAUTION:

Never start the engine.

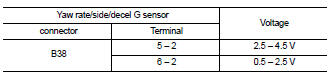

4. Check voltage between yaw rate/side/decel G sensor harness connector terminals.

CAUTION:

Never short out the terminals while measuring voltages.

Is the inspection result normal? YES >> Replace ABS actuator end electric unit (control unit). Refer to BRC-233, "Removal and Installation".

NO >> Replace yaw rate/side/decel G sensor. Refer to BRC-235, "Removal and Installation".

C1111 ABS motor, motor relay system

C1111 ABS motor, motor relay system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

C1115 wheel sensor

C1115 wheel sensor

DTC Logic

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conduc ...

Other materials:

Inspection

OIL LEAKAGE

Check rear final drive surrounding area (oil seal, drain plug, filler plug,

and carrier case, etc.) for oil leakage.

OIL LEVEL

1. Remove filler plug (1) and check oil level from filler plug mounting

hole as shown in the figure.

CAUTION:

Never start engine while checking oil l ...

P0237, P0238 TC boost sensor

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

the following procedure

before conducting the next test.

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Turn ignition swit ...

B1081 seat belt Pre-tensioner RH

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...