Nissan Juke Service and Repair Manual : Power supply and ground circuit

Diagnosis Procedure

1.INSPECTION START

Start engine.

Is engine running? YES >> GO TO 6.

NO >> GO TO 2.

2.CHECK GROUND CONNECTION-I

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace ground connection.

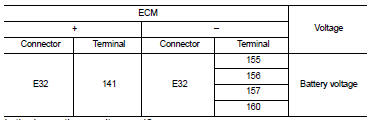

3.CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 5.

NO >> GO TO 4.

4.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors M77, E105

• 10A fuse (No. 2)

• Harness for open or short between ECM and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

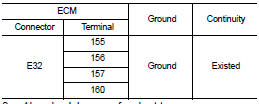

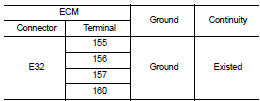

5.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Disconnect ECM harness connectors.

2. Check the continuity between ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> Repair open circuit or short to power in harness or connectors.

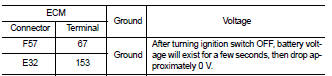

6.CHECK ECM POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 13.

NO-1 >> Battery voltage does not exist: GO TO 7.

NO-2 >> Battery voltage exists for more than a few seconds: GO TO 10.

7.CHECK ECM POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 10.

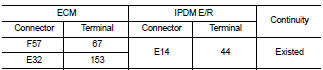

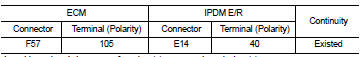

8.CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 15.

NO >> GO TO 9.

9.DETECT MALFUNCTIONING PART

Check the following.

• Harness or connectors E8, F1 • Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

10.CHECK ECM POWER SUPPLY CIRCUIT-V

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 12.

NO >> GO TO 11.

11.DETECT MALFUNCTIONING PART

Check the following.

• Harness or connectors E8, F1 • Harness for open or short between ECM and IPDM E/R

>> Repair open circuit or short to ground or short to power in harness or connectors.

12.CHECK 20A FUSE

1. Disconnect 20A fuse (No. 43) from IPDM E/R.

2. Check 20A fuse.

Is the inspection result normal? YES >> GO TO 15.

NO >> Replace 20A fuse.

13.CHECK GROUND CONNECTION-II

1. Turn ignition switch OFF.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 14.

NO >> Repair or replace ground connection.

14.CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Disconnect ECM harness connector.

2. Check the continuity between ECM harness connector and ground.

3. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 15.

NO >> Repair open circuit or short power in harness or connectors.

15.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident", ???INCIDENT SIMULATION TESTS??? and ???GROUND INSPECTION???.

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair open circuit or short to power in harness or connectors.

P0001 fuel pump

P0001 fuel pump

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC P0001 is displayed with DTC P0560 or P0657, first perform trouble

diagnosis for DTC P0560 or P0657.

Refer to EC-963, "DTC Logic" (DTC P05 ...

Other materials:

Continuously Variable Transmission (CVT)

The Continuously Variable Transmission (CVT) in your vehicle is electronically

controlled to produce maximum power and smooth operation.

The recommended operating procedures for this transmission are shown on the following

pages.

Follow these procedures for maximum vehicle performance and driv ...

B1144 diagnosis sensor unit

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...

Side air bag module

Exploded View

1. Side air bag module

2. Front seat assembly

: Do not reuse

: N·m (kg-m, in-lb)

Removal and Installation

WARNING:

• Before servicing, turn ignition switch OFF, disconnect battery negative

terminal and wait 3 minutes

or more.

• Always work from the side of air bag module. ...