Nissan Juke Service and Repair Manual : Control cable

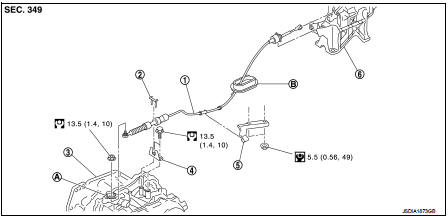

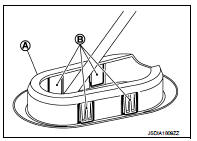

Exploded View

1. Control cable

2. Lock plate

3. Transaxle assembly

4. Bracket A

5. Bracket B

6. CVT shift selector assembly

A: Manual lever B: Grommet

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

INSTALLATION

CAUTION:

Always apply the parking brake before performing removal and installation.

1. Remove the battery. Refer to PG-124, "Removal and Installation".

2. Remove the control cable from the CVT shift selector assembly. Refer to TM-270, "Removal and Installation".

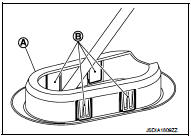

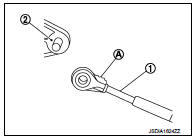

3. Disengage the pawls (B) of the grommet (A), and pull downwards to remove.

4. Remove the control cable installation nut from the manual lever.

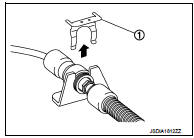

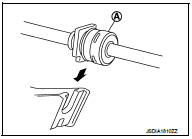

5. Remove the lock plate (1).

6. Remove center muffler from the mounting rubber and lower the center muffler downward. Refer to EX-6, "Removal and Installation".

7. Lift up the heat plate.

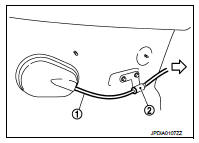

8. Remove the control cable (1) from the bracket (2).

:Vehicle front

:Vehicle front

9. Remove the control cable from the vehicle.

10. Remove bracket.

INSTALLATION

Note the following, and install in the reverse order of removal.

• From below the vehicle, press the grommet (A) into place until the pawls (B) make a click sound.

CAUTION:

• Place the grommet on the floor, then fasten it in place from

below the vehicle.

• Check that pulling down on the grommet does not disconnect it.

• Pay attention to the following when connecting the control cable to the CVT shift selector.

1. When connecting the control cable (1) to the CVT shift selector assembly (2), face the grooved surface of the rib (A) up and insert the control cable until it stops.

2. Install the socket (A) onto the CVT shift selector.

CAUTION:

• Place the socket onto the CVT shift lever, then fasten it in

place from above.

• Check that the pulling on the socket does not disconnect it.

Inspection

INSPECTION AFTER INSTALLATION

Check the CVT position. If a malfunction is found, adjust the CVT position. Refer to TM-194, "Inspection and Adjustment".

CVT shift selector

CVT shift selector

Exploded View

1. Selector lever knob

2. Lock pin

3. Knob cover

4 Position indication panel

5. CVT shift selector assembly

6. CVT shift lock unit

7. Key interlock rod*

8. Indicator lamp

...

Key interlock cable

Key interlock cable

Exploded View

1. CVT shift selector assembly

2. Key interlock cable

A: Key cylinder

B: Clip

C: Clip

Removal and Installation

REMOVAL

CAUTION:

Always apply the parking brake before perfor ...

Other materials:

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

EPS warning lamp does not turn off

Description

EPS warning lamp does not turn OFF several seconds after engine started.

Diagnosis Procedure

1.PERFORM SELF-DIAGNOSIS

With CONSULT-III

1. Turn the ignition switch OFF to ON.

2. Perform “EPS” self-diagnosis.

Is any DTC detected?

YES >> Check the DTC. Refer to STC-14, " ...

Throttle valve closed position learning

Description

Throttle Valve Closed Position Learning is a function of ECM to learn the

fully closed position of the throttle

valve by monitoring the throttle position sensor output signal. It must be

performed each time harness connector

of electric throttle control actuator or ECM is disconne ...