Nissan Juke Service and Repair Manual : How to set srt code

Description

OUTLINE

In order to set all SRTs, the self-diagnoses as in the “SRT ITEM” table must have been performed at least once. Each diagnosis may require actual driving for a long period of time under various conditions.

SRT ITEM

The table below shows required self-diagnostic items to set the SRT to “CMPLT”.

*1: Though displayed on the CONSULT-III screen, “HO2S HTR” is not SRT item.

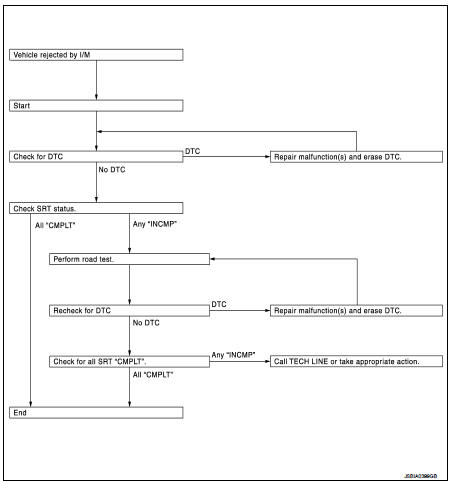

SRT SERVICE PROCEDURE

If a vehicle has failed the state emissions inspection due to one or more SRT items indicating “INCMP”, review the flowchart diagnostic sequence, referring to the following flowchart.

SRT Set Driving Pattern

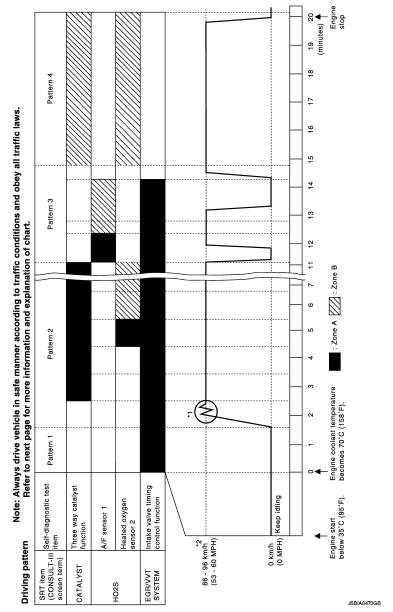

CAUTION:

Always drive the vehicle in safe manner according to traffic conditions and obey

all traffic laws.

NOTE

:

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56 MPH), then

release the accelerator pedal

and keep it released for more than 10 seconds. Depress the accelerator pedal

until vehicle speed is 90 km/

h(56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

• The time required for each diagnosis varies with road surface conditions, weather, altitude, individual driving habits, etc.

Zone A refers to the range where the time, required for the diagnosis under normal conditions*, is the shortest.

Zone B refers to the range where the diagnosis can still be performed if the diagnosis is not completed within zone A.

*: Normal conditions refer to the following:

• Sea level

• Flat road

• Ambient air temperature: 20 - 30°C (68 - 86°F)

• Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30°C (68 - 86°F)], diagnosis may also be performed.

Work Procedure

1.CHECK DTC

Check DTC.

Is any DTC detected? YES >> Repair malfunction(s) and erase DTC. Refer to EC-108, "DTC Index".

NO >> GO TO 2.

2.CHECK SRT STATUS

WITH CONSULT-III

WITH CONSULT-III

Select “SRT STATUS” in “DTC & SRT CONFIRMATION” mode of “ENGINE” using CONSULT-III.

WITHOUT CONSULT-III

WITHOUT CONSULT-III

Perform “SRT status” mode with EC-79, "On Board Diagnosis Function".

WITH GST

WITH GST

Select Service $01 with GST.

Is SRT code(s) set? YES >> END

NO-1 >> With CONSULT-III: GO TO 3.

NO-2 >> Without CONSULT-III: GO TO 4.

3.DTC CONFIRMATION PROCEDURE

1. Select “SRT WORK SUPPORT” in “DTC & SRT CONFIRMATION” mode of “ENGINE” using CONSULTIII.

2. For SRT(s) that is not set, perform the corresponding “DTC CONFIRMATION PROCEDURE” according to the “Performance Priority” in the “SRT ITEM” table. Refer to EC-142, "Description".

3. Check DTC.

Is any DTC detected? YES >> Repair malfunction(s) and erase DTC. Refer to EC-108, "DTC Index".

NO >> GO TO 9.

4.PERFORM ROAD TEST

• Check the “Performance Priority” in the “SRT ITEM” table. Refer to EC-142, "Description".

• Perform the most efficient SRT set driving pattern to set the SRT properly. Refer to EC-143, "SRT Set Driving Pattern".

In order to set all SRTs, the SRT set driving pattern must be performed at least once.

>> GO TO 5.

5.PATTERN 1

1. Check the vehicle condition; - Engine coolant temperature is −10 to 35°C (14 to 95°F).

- Fuel tank temperature is more than 0°C (32°F).

2. Start the engine.

3. Keep engine idling until the engine coolant temperature is greater than 70°C (158°F) NOTE

:

ECM terminal voltage is follows;

• Engine coolant temperature - −10 to 35°C (14 to 95°F): 3.0 - 4.3 V - 70°(158°F): Less than 1.4 V

>> GO TO 6.

6.PATTERN 2

1. Drive the vehicle. And depress the accelerator pedal until vehicle speed is 90 km/h (56 MPH), then release the accelerator pedal and keep it released for more than 10 seconds.

2. Depress the accelerator pedal until vehicle speed is 90 km/h (56 MPH) again NOTE

:

• Checking the vehicle speed with GST is advised.

• When steady-state driving is performed again even after it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

>> GO TO 7.

7.PATTERN 3

• Operate vehicle following the driving pattern shown in the figure.

• Release the accelerator pedal during deceleration of vehicle speed from 90 km/h (56 MPH) to 0 km/h (0 MPH).

>> GO TO 8.

8.PATTERN 4

• The accelerator pedal must be held very steady during steady-state driving.

• If the accelerator pedal is moved, the test must be conducted again.

>> GO TO 9.

9.CHECK SRT STATUS

WITH CONSULT-III

WITH CONSULT-III

Select “SRT STATUS” in “DTC & SRT CONFIRMATION” mode of “ENGINE” using CONSULT-III.

WITHOUT CONSULT-III

WITHOUT CONSULT-III

Perform “SRT status” mode with EC-79, "On Board Diagnosis Function".

WITH GST

WITH GST

Select Service $01 with GST.

Is SRT(s) set? YES >> END

NO >> Call TECH LINE or take appropriate action.

Fuel pressure

Fuel pressure

Work Procedure

FUEL PRESSURE RELEASE

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode of “ENGINE” using

CONSULT-III.

3. Start engine.

4. ...

Other materials:

Inside key antenna

Instrument center

INSTRUMENT CENTER : Removal and Installation

REMOVAL

1. Remove the multi display unit. Refer to AV-125, "Removal and

Installation".

2. Remove the inside key antenna (instrument center) (1) mounting

clip (A), and then remove inside key antenna (instrument

center).

...

P1212 TCS communication line

Description

This CAN communication line is used to control the smooth engine operation

during the TCS operation. Pulse

signals are exchanged between ECM and “ABS actuator and electric unit (control

unit)”.

Be sure to erase the malfunction information such as DTC not only for “ABS

actuator ...

Main line betweeN DLC and MDU circuit

Diagnosis Procedure

1.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Disconnect the following harness connectors.

- ECM

- Multi display unit

4. Check the continuity between the data link connector and the ...