Nissan Juke Service and Repair Manual : Fuel pressure

Work Procedure

FUEL PRESSURE RELEASE

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT” mode of “ENGINE” using CONSULT-III.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

Without CONSULT-III

Without CONSULT-III

1. Remove fuel pump fuse located in IPDM E/R.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel pressure.

4. Turn ignition switch OFF.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

CAUTION:

• Before disconnecting fuel line, release fuel pressure from fuel line to

eliminate danger.

• The fuel hose connection method used when taking fuel pressure check must not be used for other purposes.

• Be careful not to scratch or put debris around connection area when servicing, so that the quick connector maintains sealability with O-rings inside.

• Do not perform fuel pressure check with electrical systems operating (i.e. lights, rear defogger, A/C, etc.) Fuel pressure gauge may indicate false readings due to varying engine load and changes in manifold vacuum.

NOTE:

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pressure cannot be completely released because J10 models do not have fuel return system.

1. Release fuel pressure to zero.

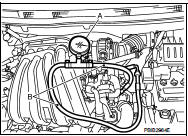

2. Prepare fuel hose for fuel pressure check B and fuel tube adapter [SST: KV10118400] D, then connect fuel pressure gauge A.

•  : To quick connector

: To quick connector

•  : To fuel tube (engine side)

: To fuel tube (engine side)

• C: Clamp

• Use suitable fuel hose for fuel pressure check (genuine NISSAN

fuel hose without quick connector).

• To avoid unnecessary force or tension to hose, use moderately long fuel hose for fuel pressure check.

• Do not use the fuel hose for checking fuel pressure with damage or cracks on it.

• Use Pressure Gauge to check fuel pressure.

3. Remove fuel hose.

• Do not twist or kink fuel hose because it is plastic hose.

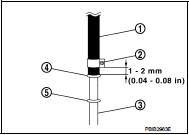

4. Connect fuel hose for fuel pressure check (1) to fuel tube (engine side) with clamp (2) as shown in the figure.

• No.2 spool (5)

• Wipe off oil or dirt from hose insertion part using cloth moistened

with gasoline.

• Apply proper amount of gasoline between top of the fuel tube (3) and No.1 spool (4).

• Insert fuel hose for fuel pressure check until it touches the No.1 spool on fuel tube.

• Use NISSAN genuine hose clamp (part number: 16439 N4710 or 16439 40U00).

• When reconnecting fuel line, always use new clamps.

• Use a torque driver to tighten clamps.

• Install hose clamp to the position within 1 - 2 mm (0.04 - 0.08 in).

Tightening torque: 1 - 1.5 N·m (0.1 - 0.15 kg-m, 9 - 13 in-lb)

• Make sure that clamp screw does not contact adjacent parts.

5. Connect fuel tube adapter to quick connector.

• A: Fuel pressure gauge • B: Fuel hose for fuel pressure check 6. After connecting fuel hose for fuel pressure check, pull the hose with a force of approximately 98 N (10 kg, 22 lb) to confirm fuel tube does not come off.

7. Turn ignition switch ON and check for fuel leakage.

8. Start engine and check for fuel leakage.

9. Read the indication of fuel pressure gauge.

• Do not perform fuel pressure check with system operating.

Fuel pressure gauge may indicate false readings.

• During fuel pressure check, confirm for fuel leakage from fuel connection every 3 minutes.

At idling: Approximately 350 kPa (3.5 bar, 3.57 kg/cm2, 51 psi)

10. If result is unsatisfactory, go to next step.

11. Check the following.

• Fuel hoses and fuel tubes for clogging

• Fuel filter for clogging

• Fuel pump

• Fuel pressure regulator for clogging

If OK, replace fuel pressure regulator.

If NG, repair or replace.

Mixture ratio self-learning value

clear

Mixture ratio self-learning value

clear

Description

This describes how to erase the mixture ratio self-learning value. For the

actual procedure, follow the instructions

in “Diagnosis Procedure”.

Work Procedure

With CONSULT-III

1. Sta ...

How to set srt code

How to set srt code

Description

OUTLINE

In order to set all SRTs, the self-diagnoses as in the “SRT ITEM” table must

have been performed at least

once. Each diagnosis may require actual driving for a long period of ...

Other materials:

On board diagnostic (OBD) system

Diagnosis Description

DESCRIPTION

The CVT system has two self-diagnostic systems.

The first is the emission-related on board diagnostic system (OBD) performed by

the TCM in combination with

the ECM. The malfunction is indicated by the MIL (malfunction indicator lamp)

and is stored as a DTC ...

Vehicle Recovery (Freeing a Stuck Vehicle)

FRONT

1. Remove the hook cover from the bumper using a remover tool.

2. Securely install the vehicle recovery hook stored with jacking

tools.

Check that the hook is properly secured in the stored place after use.

WARNING:

• Stand clear of a stuck vehicle.

• Never spin your tires at high spe ...

Blower motor

Exploded View

2WD models

1. A/C unit assembly

2. Fan control amp.*1

3. Blower fan resistor*2

4. Blower motor

5. Blower motor cover

• *1: Automatic air conditioner

• *2: Manual air conditioner or Manual heater

4WD models

1. A/C unit assembly

2. Blower fan resistor*1

3. Sub harnes ...