Nissan Juke Service and Repair Manual : Fuel pump

Component Function Check

1.CHECK FUEL PUMP FUNCTION

1. Turn ignition switch ON.

2. Pinch fuel feed hose with two fingers.

Fuel pressure pulsation should be felt on the fuel feed hose for 1 second after ignition switch is turned ON.

Is the inspection result normal? YES >> INSPECTION END

NO >> EC-780, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Turn ignition switch ON.

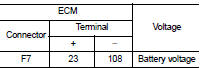

4. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 2.

2.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R harness connector.

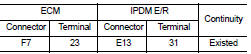

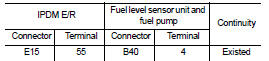

3. Check the continuity between IPDM E/R harness connector and ECM harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• Harness or connectors E8, F1 • IPDM E/R connector E13 • Harness for open or short to ground and short power

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-III

1. Turn ignition switch OFF.

2. Reconnect all harness connectors disconnected.

3. Disconnect “fuel level sensor unit and fuel pump” harness connector.

4. Turn ignition switch ON.

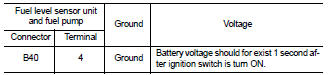

5. Check voltage between “fuel level sensor unit and fuel pump” harness connector and ground.

Is the inspection result normal? YES >> GO TO 8.

NO >> GO TO 5.

5.CHECK 15 A FUSE

1. Turn ignition switch OFF.

2. Disconnect 15 A fuse (No. 60) from IPDM E/R.

3. Check 15 A fuse.

Is the inspection result normal? YES >> GO TO 6.

NO >> Replace fuse.

6.CHECK FUEL PUMP POWER SUPPLY CIRCUIT-IV

1. Disconnect IPDM E/R harness connector.

2. Check the continuity between IPDM E/R harness connector and “fuel level sensor unit and fuel pump” harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 10.

NO >> GO TO 7.

7.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E105, M77 • Harness connectors B1, M18 • Harness for open or short between IPDM E/R and “fuel level sensor unit and fuel pump”

>> Repair open circuit or short to ground or short to power in harness or connectors.

8.CHECK FUEL PUMP GROUND CIRCUIT

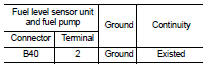

1. Check the continuity between “fuel level sensor unit and fuel pump” and ground.

2. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair open circuit or short to power in harness or connectors.

9.CHECK FUEL PUMP

Refer to EC-782, "Component Inspection".

Is the inspection result normal? YES >> GO TO 10.

NO >> Replace “fuel level sensor unit and fuel pump”.

10.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness or connectors.

Component Inspection

1.CHECK FUEL PUMP

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness connector.

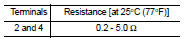

3. Check resistance between “fuel level sensor unit and fuel pump” terminals as follows.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace “fuel level sensor unit and fuel pump”.

Fuel injector

Fuel injector

Component Function Check

1.INSPECTION START

Turn ignition switch to START.

Is any cylinder ignited?

YES >> GO TO 2.

NO >> Go to EC-778, "Diagnosis Procedure".

2.CHECK ...

Ignition signal

Ignition signal

Component Function Check

1.INSPECTION START

Turn ignition switch OFF, and restart engine.

Does the engine start?

YES-1 >> With CONSULT-III: GO TO 2.

YES-2 >> Without CONSULT-III: ...

Other materials:

Back door lock

Exploded View

1. Back door lock assembly

2. TORX bolt

3. Back door striker

: Do not reuse

: N·m (kg-m, ft-lb)

: Body grease

Door lock

DOOR LOCK : Removal and Installation

REMOVAL

1. Remove the back door lower finisher. Refer to INT-35, "BACK DOOR LOWER

FINISHER : Removal and

In ...

Headlamp (HI) circuit

Component Function Check

1.CHECK HEADLAMP (HI) OPERATION

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2. With operating the test items, check that the headlamp (HI) is turned ON.

Hi : Headlamp (HI) ON

Off : Headlamp (HI) OFF

NOTE:

ON/OFF is repeated 1 seco ...

A/C unit assembly

Exploded View (Automatic Air Conditioning)

REMOVAL

LHD models (4WD)

1. A/C unit assembly

2. Drain hose

3. Steering member

4. Instrument stay

: Clip

: N·m (kg-m, ft-lb)

DISASSEMBLY

LHD models (4WD)

1. Ventilator seal

2. Defroster seal

3. Upper attachment case

4. Sub defroster do ...