Nissan Juke Service and Repair Manual : Front suspension member

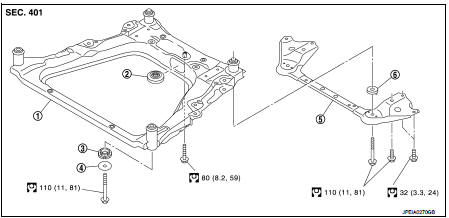

Exploded View

2WD

1. Front suspension member

2. Damper assembly*

3. Rebound stopper rubber

4. Washer

5. Member stay

6. Rebound stopper

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

*: For K9K models

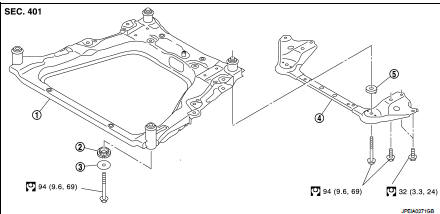

4WD

1. Front suspension member

2. Rebound stopper rubber

3. Washer

4. Member stay

5. Rebound stopper

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

1. Separate intermediate shaft from steering gear assembly. Refer to ST-14, "Removal and Installation".

2. Remove tires. Refer to WT-7, "Removal and Installation".

3. Remove front under cover.

4. Separate stabilizer connecting rod from strut assembly. Refer to FSU-16, "Removal and Installation".

5. Separate steering outer socket from steering knuckle. Refer to ST-19, "Removal and Installation".

6. Separate transverse link from steering knuckle.

• MR16DDT: Refer to FAX-11, "Removal and Installation".

• HR16DE: Refer to FAX-43, "Removal and Installation".

• K9K: Refer to FAX-68, "Removal and Installation".

7. Remove rear torque rod.

• MR16DDT: Refer to EM-55, "2WD : Removal and Installation".

• HR16DE: Refer to EM-215, "Removal and Installation".

• K9K: Refer to EM-326, "Removal and Installation".

8. Set suitable jack under front suspension member.

CAUTION:

Check the stable condition when using a jack.

9. Remove member stay and rebound stopper.

10. Remove suspension member mounting bolts, washer, and rebound stopper rubber.

11. Gradually lower the jack to remove front suspension member from vehicle body.

CAUTION:

Operate while checking that jack supporting status is stable.

NOTE:

Remove it with each component parts.

12. Remove damper assembly from front suspension member. (K9K models only) 13. Remove component parts from front suspension member.

14. Perform inspection after removal. Refer to FSU-14, "Inspection".

INSTALLATION

Note the following, and install in the reverse order of removal.

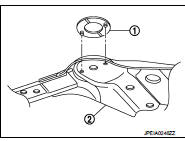

• To install rebound stopper (1), insert it with the protrusion aligned with the hole of member stay (2).

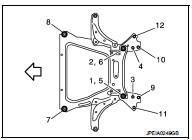

• To install member stay and mounting bolts of front suspension member, temporarily tighten the bolts before tightening to the specified torque, referring to the tightening method and the numerical order shown below:

Temporary tightening : 1 → 2 Final tightening (Specified torque) : 3 → 4 → 5 → 6 → 7 → 8 → 9 → 10 → 11 → 12

: Vehicle front

: Vehicle front

• Perform final tightening of bolts and nuts at the vehicle installation position (rubber bushing), under unladen conditions with tires on level ground.

• Perform inspection after installation. Refer to FSU-14, "Inspection".

Inspection

INSPECTION AFTER REMOVAL

Check front suspension member for cracks, wear or damage. Replace it if necessary.

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connector.

2. Check wheel alignment. Refer to FSU-7, "Inspection".

Front stabilizer

Front stabilizer

Exploded View

1. Stabilizer bar

2. Stabilizer clamp

3. Stabilizer bushing

4. Stabilizer connecting rod

5. Strut assembly

6. Front suspension member

: N·m (kg-m, ft-lb)

Removal and Instal ...

Other materials:

Diagnosis system (BCM)

Common item

COMMON ITEM : CONSULT-III Function (BCM - COMMON ITEM)

APPLICATION ITEM

CONSULT-III performs the following functions via CAN communication with BCM.

SYSTEM APPLICATION

BCM can perform the following functions for each system.

NOTE:

It can perform the diagnosis modes except the ...

Basic inspection

DIAGNOSIS AND REPAIR WORK FLOW

Work Flow

DESCRIPTION OF TROUBLE DIAGNOSIS FLOWCHART

DETAILS OF TROUBLE DIAGNOSIS FLOWCHART

1.OBTAIN INFORMATION ABOUT SYMPTOM

Interview the customer to obtain as much information as possible about the

conditions and environment under

which the malfunction oc ...

Door does not lock/unlock with door lock and unlock

switch

All door

ALL DOOR : Description

All doors do not lock/unlock using door lock and unlock switch.

ALL DOOR : Diagnosis Procedure

1.CHECK DOOR LOCK AND UNLOCK SWITCH

Check door lock and unlock switch. Refer to the following.

• Driver side: Refer to DLK-391, "DRIVER SIDE : Component Functio ...