Nissan Juke Service and Repair Manual : Drive pinion

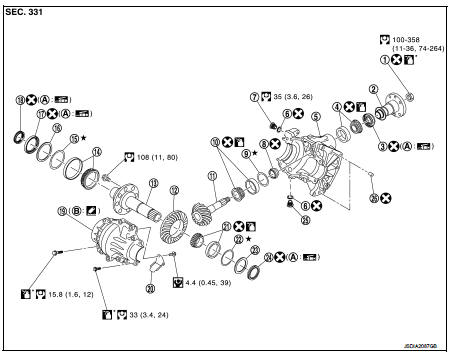

Exploded View

1. Pinion lock nut

2. Companion flange

3. Drive pion oil seal

4. Pinon rear bearing

5. Transfer case

6. Gasket

7. Filler plug

8. Collapsible spacer

9. Drive pinion adjust shim

10. Drive pinion

11. Pinion front bearing

12. Ring gear

13. Ring gear shaft

14. Ring gear bearing (right)

15. Ring gear bearing adjust shim (right)

16. Spacer (right)

17. Transfer case oil seal (right)

18. Drive shaft oil seal

19. Transfer cover

20. Oil defense

21. Ring gear bearing (left)

22. Ring gear bearing adjust shim (left)

23. Spacer (left)

24. Transfer case oil seal (left)

25. Drain plug

26. Dowel pin

A. Oil seal lip

B. Transfer case mounting face

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

: Apply gear oil.

: Apply gear oil.

: Apply anti-corrosive oil.

: Apply anti-corrosive oil.

: Apply multi purpose grease

: Apply multi purpose grease

: Apply Genuine Liquid Gasket 1215

: Apply Genuine Liquid Gasket 1215

or equivalent.

: Select with proper thickness.

: Select with proper thickness.

Disassembly

1. Remove transfer cover. Refer to DLN-114, "Disassembly".

2. Remove ring gear shaft assembly. Refer to DLN-96, "Disassembly".

3. Remove lock nut from the drive pinion.

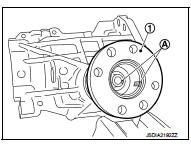

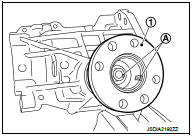

4. Put matching marks (A) on screw ends of companion flange (1) and drive pinion.

CAUTION:

Use paint to avoid scratching the surface.

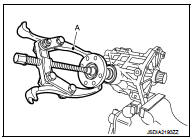

5. Remove companion flange from drive pinion with a puller (A).

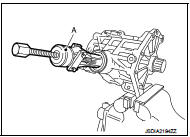

6. Remove drive pinion oil seal from the transfer case with a puller (A) (SST: KV381054S0).

CAUTION:

Never damage transfer case.

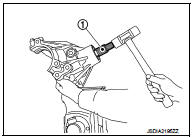

7. Remove drive pinion assembly (1) from transfer case while tapping the drive pinion lightly with a plastic hammer.

CAUTION:

Never drop the drive pinion assembly.

8. Remove collapsible spacer from the drive pinion.

9. Remove inner race of drive pinion bearing (rear side) from transfer case.

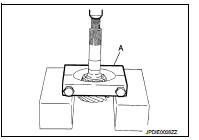

10. Remove inner race of drive pinion bearing (front side) from drive pinion with a replacer (A) (commercial service tool).

11. Remove drive pinion adjusting shim from the drive pinion.

12. Perform inspection after disassembly. Refer to DLN-111, "Inspection".

Assembly

1. Select drive pinion adjusting shim. Refer to DLN-98, "Adjustment".

2. Install selected drive pinion adjusting shim to drive pinion.

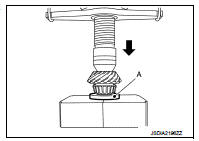

3. Install inner race of drive pinion bearing (front side) to drive pinion with a drift (A) (SST: ST35272000).

CAUTION:

• Never reuse drive pinion bearing (front side).

• Apply gear oil to the drive pinion bearing (front side).

4. Assemble the inner race of drive pinion bearing (rear side) into the transfer case.

CAUTION:

• Never reuse drive pinion bearing (rear side).

• Apply gear oil to the drive pinion bearing (rear side).

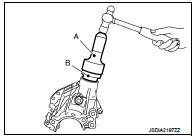

5. Install drive pinion oil seal to transfer case with drifts so that it becomes flush with case end surface with the drifts (A and B).

A : Drift (SST: KV38102510) B : Drift (SST: ST30720000)

CAUTION:

• Never reuse oil seal.

• Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference.

6. Assemble a collapsible spacer onto the drive pinion.

CAUTION:

Never reuse the collapsible spacer.

7. Assemble drive pinion assembly into the transfer case, and then install companion flange (1) to drive pinion.

NOTE

:

Align matching marks (A) on the thread edge of companion

flange and drive pinion and install companion flange if drive pinion

is reused.

8. Tap the companion flange (1) with a plastic hammer as far as the lock nut can be tightened.

CAUTION:

Never damage drive pinion oil seal.

9. Apply anti-corrosive oil to the thread and seat of the lock nut, and temporarily tighten lock nut to the drive pinion.

CAUTION:

Never reuse lock nut.

10. Tighten lock nut within the specified torque range with a preload gauge (A) (SST: ST3127S000) so that the drive pinion bearing preload is within standard.

Drive pinion bearing preload : Refer to DLN-117, "Preload Torque".

CAUTION:

• Start the tightening of lock nut from lower limit of the

specified torque. Check the preload every 5° to 10° while

tightening the lock nut.

• Replace the collapsible spacer and tighten it again to adjust if preload exceeds the specified value. Never loosen lock nut to adjust preload.

• After adjustment, rotate the drive pinion back and forth from 2 to 3 times to check for unusual noise, sticking, binding, and so on.

11. Install ring gear shaft assembly. Refer to DLN-97, "Assembly".

12. Install transfer cover. Refer to DLN-114, "Assembly".

13. Check backlash, tooth contact, total preload and companion flange runout. Refer to DLN-98, "Adjustment".

CAUTION:

Measure the total preload without the transfer case oil seal.

Adjustment

About adjusting of drive pinion, refer to DLN-98, "Adjustment".

Inspection

INSPECTION AFTER DISASSEMBLY

Check items below. If necessary, replace them with new ones.

Gear and Shaft Check gear face and shaft for wear, cracks, damage, and seizure.

CAUTION:

Replace ring gear and drive pinion as a set (hypoid gear set) if any malfunction

is detected on the ring

gear or drive pinion.

Bearing

Check for seizure, peeling, wear, corrosion, sticking, unusual noise, roughness

in hand turning, and other

damage.

CAUTION:

Always replace inner race and outer race as a pair when replacing the bearing.

Shim

Check for seizure, damage, and unusual wear.

Case

Check the bearing mounting surface for wear, cracks and damages.

CAUTION

:

Replace transfer case and transfer cover as a set if any malfunction is detected

on transfer case or

transfer cover.

Ring gear shaft

Ring gear shaft

Exploded View

1. Pinion lock nut

2. Companion flange

3. Drive pion oil seal

4. Pinon rear bearing

5. Transfer case

6. Gasket

7. Filler plug

8. Collapsible spacer

9. Drive pinion adjus ...

Transfer case

Transfer case

Exploded View

1. Pinion lock nut

2. Companion flange

3. Drive pion oil seal

4. Pinon rear bearing

5. Transfer case

6. Gasket

7. Filler plug

8. Collapsible spacer

9. Drive pinion adjus ...

Other materials:

On board diagnostic (OBD) system

Diagnosis Description

The ECM controls the display on the instrument panel of certain information

relating to the operation of the

engine.

Four functions are involved here: The OBD malfunction indicator [MI (Yellow)]

for the EOBD (European On

Board Diagnostics), the pre/post heating, the e ...

Components

• THE LARGE ILLUSTRATIONS are exploded views (see the following) and

contain tightening torques, lubrication

points, section number of the PARTS CATALOG (e.g. SEC. 440) and other

information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. ...

Line pressure test

Work Procedure

INSPECTION

1. Check the engine oil level. Replenish if necessary. LU-25, "Inspection".

2. Check for leak of the CVT fluid. Refer to TM-480, "Inspection".

3. Drive for about 10 minutes to warm up the vehicle so that the CVT fluid

temperature is 50 to 80°C (122 ...