Nissan Juke Service and Repair Manual : Transfer case

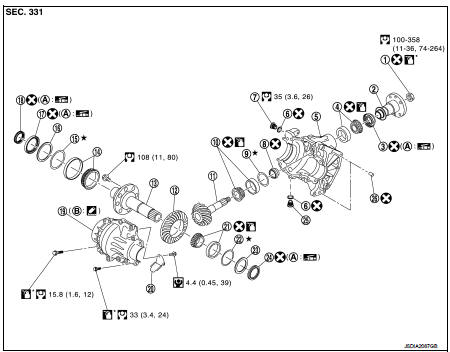

Exploded View

1. Pinion lock nut

2. Companion flange

3. Drive pion oil seal

4. Pinon rear bearing

5. Transfer case

6. Gasket

7. Filler plug

8. Collapsible spacer

9. Drive pinion adjust shim

10. Drive pinion

11. Pinion front bearing

12. Ring gear

13. Ring gear shaft

14. Ring gear bearing (right)

15. Ring gear bearing adjust shim (right)

16. Spacer (right)

17. Transfer case oil seal (right)

18. Drive shaft oil seal

19. Transfer cover

20. Oil defense

21. Ring gear bearing (left)

22. Ring gear bearing adjust shim (left)

23. Spacer (left)

24. Transfer case oil seal (left)

25. Drain plug

26. Dowel pin

A. Oil seal lip

B. Transfer case mounting face

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

: Apply gear oil.

: Apply gear oil.

: Apply anti-corrosive oil.

: Apply anti-corrosive oil.

: Apply multi purpose grease

: Apply multi purpose grease

: Apply Genuine Liquid Gasket 1215

: Apply Genuine Liquid Gasket 1215

or equivalent.

: Select with proper thickness.

: Select with proper thickness.

Disassembly

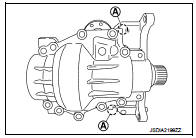

1. Remove transfer cover mounting bolts.

2. Lightly tap (A) position of transfer cover with a plastic hammer to remove transfer cover.

3. Remove ring gear shaft assembly. Refer to DLN-96, "Disassembly",

4. Tap the outer race of drive pinion bearing from transfer case with a brass rod to remove outer race of drive pinion bearing (front side and rear side).

CAUTION:

Never damage transfer case.

5. Remove dowel pin.

CAUTION:

Never remove dowel pin, if it is not necessary to replace.

6. Remove the filler plug and drain plug from the transfer case, and then remove each gasket.

7. Remove oil defense from transfer cover.

8. Perform inspection after disassembly. Refer to DLN-116, "Inspection".

Assembly

1. Install the oil defense to transfer cover.

2. Install gaskets onto filler plug and drain plug and install them into transfer case.

CAUTION:

• Never reuse gaskets.

• Install filler plug after oil is filled.

3. Install the dowel pin to transfer case.

CAUTION:

Never reuse the dowel pin.

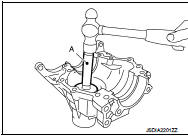

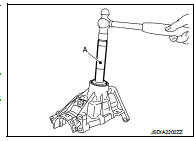

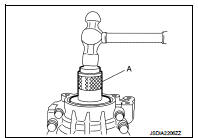

4. Install outer race of drive pinion bearing (front side) to the transfer case with drift (A) (SST: ST17130000).

CAUTION:

• Never reuse drive pinion bearing (front side).

• Apply gear oil to the drive pinion bearing (front side)

5. Install outer race of drive pinion bearing (rear side) to transfer case with a drift (A) (SST: ST33230000).

CAUTION:

• Never reuse drive pinion bearing (rear side).

• Apply gear oil to the drive pinion bearing (rear side).

6. Install drive pinion assembly to transfer case. Refer to DLN-110, "Assembly".

7. Install ring gear shaft assembly to transfer case. Refer to DLN- 97, "Assembly".

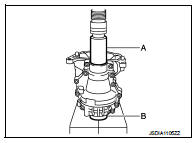

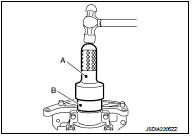

8. Set the drifts (A and B) to right and left side spacers individually.

Compress ring gear shaft assembly and ring gear bearing to install transfer cover to transfer case.

A : Drift (commercial service tool) B : Drift (commercial service tool)

CAUTION:

• Clean the mounting surface of transfer case and transfer

cover to degrease sufficiently.

• Never apply gasket fluid on the mounting surface.

• The drift shall be placed on the center of the spacers.

• The pressure shall be as low as to install ring gear shaft assembly into transfer case. The maximum pressure shall be 10 kN (1 ton, 1.0 Imp ton).

• If the adjusting shims and spacers are installed by tapping, the transfer cover may be damaged.

Avoid tapping.

9. Check backlash, tooth contact, total preload and companion flange runout. Refer to DLN-98, "Adjustment".

CAUTION:

Measure the total preload without the transfer case oil seals.

10. Remove transfer cover. Refer to DLN-114, "Disassembly".

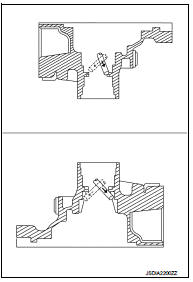

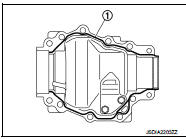

11. Apply liquid gasket (1) to mating surface of rear cover.

CAUTION:

• Remove old gasket adhering to the mounting surfaces.

Also remove any moisture, oil, or foreign material adhering to the mounting surfaces.

• Overlap both ends of the bead for at least 3 mm (0.12 in).

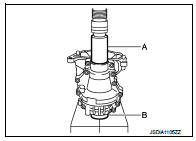

12. Set the drifts (A and B) to right and left side spacers individually.

Compress ring gear shaft assembly and ring gear bearing to install transfer cover to transfer case.

A : Drift (commercial service tool) B : Drift (commercial service tool)

CAUTION:

• Immediately install after applying gasket.

• The drift shall be placed on the center of the spacers.

• The pressure shall be as low as to install ring gear shaft assembly into transfer case. The maximum pressure shall be 10 kN (1 ton, 1.0 Imp ton).

• If the adjusting shims and spacers are installed by tapping, the transfer cover may be damaged.

Avoid tapping.

13. Tighten rear cover mounting bolts to the specified torque.

14. Install transfer case oil seal (right side) until it becomes flush with ring gear shaft end, using the drifts (A and B).

A : Drift (SST: ST30720000) B : Drift (SST: ST19820000)

CAUTION:

• Never reuse oil seals.

• When installing, do not incline oil seals.

• Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

• Immediately install after installing transfer cover.

15. Install transfer case oil seal (left side) until it becomes flush with ring gear shaft end, using the drift (A) (SST: KV40100620).

CAUTION:

• Never reuse oil seals.

• When installing, do not incline oil seals.

• Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

• Immediately install after installing transfer cover.

• After installing oil seal, immediately wipe out gasket squeezed out inward of transfer case.

Inspection

INSPECTION AFTER DISASSEMBLY

Check items below. If necessary, replace them with new ones.

Case

Check the bearing mounting surface for wear, cracks and damages.

CAUTION:

Replace transfer case and transfer cover as a set if any malfunction is detected

on transfer case or

transfer cover.

Drive pinion

Drive pinion

Exploded View

1. Pinion lock nut

2. Companion flange

3. Drive pion oil seal

4. Pinon rear bearing

5. Transfer case

6. Gasket

7. Filler plug

8. Collapsible spacer

9. Drive pinion adjus ...

Other materials:

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

Remote keyless entry system (if so equipped)

It is possible to lock/unlock all doors (including the lift gate), and activate

the panic alarm by using the keyfob from outside the vehicle.

Before locking the doors, make sure the key is not left in the vehicle.

The keyfob can operate at a distance of approximately 33 ft (10 m) from the vehic ...

P0132 A/F sensor 1

DTC Logic

DTC DETECTION LOGIC

To judge the malfunction, the diagnosis checks that the A/F signal computed

by ECM from the A/F sensor 1

signal is not inordinately high.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If DTC Confirmation Procedure has been previously conducted, always perform

...