Nissan Juke Service and Repair Manual : Cooling fan

Exploded View

1. Fan motorCooling fan

2. Fan shroud

3. Cooling fan

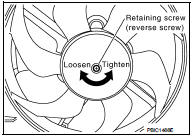

A. Reverse screw

: Apply thread locking sealant.

: Apply thread locking sealant.

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

1. Drain engine coolant. Refer to CO-62, "Draining".

2. Disconnect radiator hose (lower) clip.

3. Remove battery. Refer to PG-124, "Exploded View" 4. Remove air duct (inlet). Refer to EM-280, "Exploded View".

5. Remove fusible link and relay box bracket, and put fusible link and relay box aside.

6. Remove reservoir tank.

7. Disconnect fan motor connector and boost pressure control valve harness connector, and put the connectors aside.

8. Remove boost pressure control valve assembly. Refer to EC-825, "TURBOCHARGER BOOST CONTROL : Vacuum Hose Drawing".

9. Remove radiator upper hose. Refer to CO-66, "Exploded View".

10. Remove radiator fan and shroud assembly.

11. Remove radiator fan reverse screw.

12. Remove fan motor from fan shroud.

INSTALLATION

Install in the reverse order of removal.

Radiator

Radiator

Exploded View

1. Reservoir tank cap

2. Reservoir tank

3. Clamp

4. Reservoir tank hose

5. Mounting rubber (upper)

6. Reservoir tank hose

7. Radiator

8. Mounting rubber (lower)

9. Drain ...

Water pump

Water pump

Exploded View

1. Water pump

2. Gasket

3. Cylinder block

Removal and Installation

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur

from high pressure ...

Other materials:

Waxing

Regular waxing protects the paint surface and helps retain new vehicle appearance.

Polishing is recommended to remove built-up wax residue and to avoid a weathered

appearance before reapplying wax.

A NISSAN dealer can assist you in choosing the proper product.

• Wax your vehicle only after a t ...

Light & rain sensor

Exploded View

CAUTION:

When the light & rain sensor is removed from windshield, the light & rain sensor

cannot be re-used.

REMOVAL

1. Light & rain sensor bracket

2. Mirror base

3. Light & rain sensor

4. Inside mirror assembly

: Pawl

: Do not reuse

Removal and Installa ...

Hood switch

Component Function Check

1.CHECK FUNCTION

1. Select “HOOD SW” in “Data Monitor” mode of “IPDM E/R” using CONSULT-III.

2. Check “HOOD SW” indication under the following condition.

Is the indication normal?

YES >> Hood switch is OK.

NO >> Go to SEC-223, "Diagnosis Procedure& ...