Nissan Juke Service and Repair Manual : Front wiper motor hi circuit

Component Function Check

1.CHECK FRONT WIPER HI OPERATION

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation.

Hi : Front wiper (HI) operation Off : Stop the front wiper

Is front wiper (HI) operation normally? YES >> Front wiper motor HI circuit is normal.

NO >> Refer to WW-39, "Diagnosis Procedure".

Diagnosis Procedure

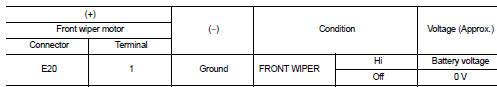

1.CHECK FRONT WIPER MOTOR (HI) OUTPUT VOLTAGE

CONSULT-III ACTIVE TEST

CONSULT-III ACTIVE TEST

1. Turn ignition switch OFF.

2. Disconnect front wiper motor connector.

3. Turn ignition switch ON.

4. Select “FRONT WIPER” of IPDM E/R active test item.

5. With operating the test item, check voltage between front wiper motor harness connector and ground.

Is the inspection result normal? YES >> Replace front wiper motor.

NO >> GO TO 2.

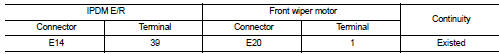

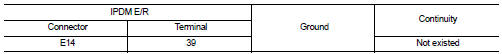

2.CHECK FRONT WIPER MOTOR (HI) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R connector.

3. Check continuity between IPDM E/R harness connector and front wiper motor harness connector.

4. Check continuity between IPDM E/R harness connector and ground.

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair or replace harness.

Front wiper motor lo circuit

Front wiper motor lo circuit

Component Function Check

1.CHECK FRONT WIPER LO OPERATION

CONSULT-III ACTIVE TEST

1. Select “FRONT WIPER” of IPDM E/R active test item.

2. With operating the test item, check front wiper operation ...

Front wiper auto stop signal circuit

Front wiper auto stop signal circuit

Component Function Check

1.CHECK FRONT WIPER (AUTO STOP) SIGNAL

CONSULT-III DATA MONITOR

1. Select “WIP AUTO STOP” of IPDM E/R data monitor item.

2. Operate the front wiper.

3. With the front wip ...

Other materials:

Precautions for Drive Shaft

• Observe the following precautions when disassembling and assembling drive

shaft.

- Never disassemble joint sub-assembly because it is non-overhaul parts.

- Perform work in a location which is as dust-free as possible.

- Clean the parts, before disassembling and assembling.

- Prevent the entr ...

P1610 lock mode

Description

ECM forcibly switches to the mode that inhibits engine start, when engine

start operation is performed 5 times

or more while communication between ECM and BCM is not normal.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Turn i ...

Front suspension assembly

Inspection

COMPONENT PART

Check the mounting conditions (looseness, backlash) of each component and

component conditions (wear,

damage) are normal.

BALL JOINT AXIAL END PLAY

1. Set front wheels in a straight-ahead position.

2. Measure axial end play by prying it up/down with iron bar or eq ...