Nissan Juke Service and Repair Manual : Compression pressure

Inspection

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-551, "Work Procedure".

3. Remove ignition coil and spark plug from each cylinder. Refer to EM-178, "Exploded View".

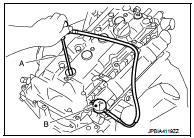

4. Connect engine tachometer (not required in use of CONSULT-III).

5. Install compression gauge (B) with an adapter (A) (commercial service tool) onto spark plug hole.

• Use the adapter whose picking up end inserted to spark plug hole is smaller than 20 mm (0.79 in) in diameter. Otherwise, it may be caught by cylinder head during removal.

a : 20 mm (0.79 in)

6. With accelerator pedal fully depressed, turn ignition switch to “START” for cranking. When the gauge pointer stabilizes, read the compression pressure and the engine rpm. Perform these steps to check each cylinder.

Compression pressure : Refer to EM-250, "General Specification".

CAUTION:

Always use a fully charged battery to obtain the specified engine speed.

• If the engine speed is out of the specified range, check battery liquid for proper gravity. Check the engine speed again with normal battery gravity. Refer to PG-111, "How to Handle Battery".

• If compression pressure is below minimum value, check valve clearances, and parts associated with combustion chamber (valve, valve seat, piston, piston ring, cylinder bore, cylinder head, and cylinder head gasket). After the checking, measure compression pressure again.

• If some cylinder has low compression pressure, pour small amount of engine oil into the spark plug hole of the cylinder to recheck it for compression.

- If the added engine oil improves the compression, piston rings may be worn out or damaged. Check piston rings and replace if necessary.

- If the compression pressure remains at low level despite the addition of engine oil, valves may be malfunctioning.

Check valves for damage. Replace valve or valve seat accordingly.

• If two adjacent cylinders have respectively low compression pressure and their compression remains low even after the addition of engine oil, cylinder head gaskets are leaking. In such a case, replace cylinder head gaskets.

7. After inspection is completed, install removed parts.

8. Start the engine, and check that the engine runs smoothly.

9. Perform trouble diagnosis. If DTC appears, erase it. Refer to EC-558, "Description".

Camshaft valve clearance

Camshaft valve clearance

Inspection and Adjustment

INSPECTION

Perform inspection as follows after removal, installation or replacement of

camshaft or valve-related parts, or if

there is unusual engine conditions regardin ...

Symptom diagnosis

Symptom diagnosis

Noise, vibration and harshness

(NVH) Troubleshooting

NVH troubleshooting Chart

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine. ...

Other materials:

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

NOTE:

• Before removing and installing any control units, first turn the ignition

switch to the LOCK position, then disconnect

both battery cables.

• After finishing work, confirm that all control unit connectors are connected

properly, then re-connect both

battery cables.

• Always use CONS ...

Daytime running light relay circuit

Component Function Check

1.CHECK DAYTIME RUNNING LIGHT OPERATION

CONSULT-III ACTIVE TEST

1. Select “EXTERNAL LAMPS” of IPDM E/R active test item.

2. With operating the test item, check that parking lamp, tail lamp and license

plate lamp are turned ON.

TAIL : Parking lamp, tail lamp and licens ...

Hood

Exploded View

1. Hood assembly

2. Hood bumper rubber

3. Radiator core seal

4. Hood bumper rubber

5. Clamp

6. Hood hinge

7. Grommet

8. Hood support rod

: Clip

: Pawl

: Body grease

Hood assembly

HOOD ASSEMBLY : Removal and Installation

CAUTION:

• Operate with two workers, because ...