Nissan Juke Service and Repair Manual : Clutch pedal position switch

Component Function Check

1.CHECK CLUTCH PEDAL POSITION SWITCH FUNCTION

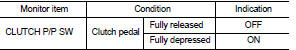

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “ENGINE” using CONSULT-III.

3. Select “CLUTCH P/P SW” in “DATA MONITOR” mode.

4. Check “CLUTCH P/P SW” indication under the following conditions.

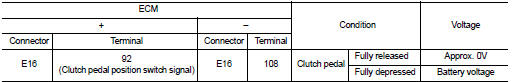

Without CONSULT-III

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-771, "Diagnosis Procedure".

Diagnosis Procedure

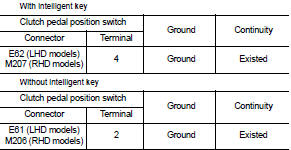

1.CHECK CLUTCH PEDAL POSITION SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect clutch pedal position switch harness connector.

3. Check the continuity between clutch pedal position switch harness connector and ground.

4. Also check harness for short to power.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair open circuit or short to power in harness or connectors.

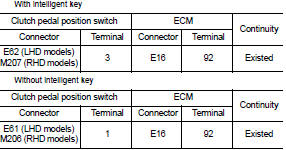

2.CHECK CLUTCH PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check the continuity between clutch pedal position switch harness connector and ECM harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK CLUTCH PEDAL POSITION SWITCH

Refer to EC-772, "Component Inspection".

Is the inspection result normal? YES >> GO TO 4.

NO >> Replace clutch pedal position switch.

4.CHECK INTERMITTENT INCIDENT

Refer to GI-42, "Intermittent Incident".

>> INSPECTION END

Component Inspection

1.CHECK CLUTCH PEDAL POSITION SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect clutch pedal position switch harness connector.

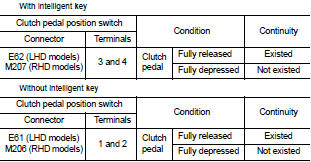

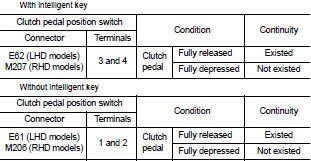

3. Check the continuity between clutch pedal position switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK CLUTCH PEDAL POSITION SWITCH-II

1. Adjust clutch pedal position switch installation. Refer to CL-7, "Inspection and Adjustment".

2. Check the continuity between clutch pedal position switch terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace clutch pedal position switch.

ASCD main switch

ASCD main switch

Component Function Check

1.CHECK ASCD MAIN SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “ENGINE” using CONSULT-III.

3. Select “MAIN SW” in “DATA MONITOR” mode.

4. Check ...

Cooling fan

Cooling fan

Component Function Check

1.CHECK COOLING FAN FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “COOLING FAN” in “ACTIVE TEST” mode with CONSULT-III.

3. Touch “LOW” and “Hi” on the ...

Other materials:

DPF (diesel particulate filter) data clear

Description

Perform ???DIESEL PARTICULATE FILTER DATA CLEAR??? in ???WORK SUPPORT??? mode with

CONSULT-III

when oxidation catalyst with diesel particulate filter is replaced as new one.

Based on the signal from sensors

ECM estimates the amount of particulate matter in diesel particulate filte ...

Models without Intelligent Key system

1. Apply the parking brake.

2. Continuously Variable Transmission (CVT) models:

Move the shift lever to the P (Park) or N (Neutral) position. (P is recommended.)

The starter is designed so that it does not operate unless the shift lever is in

either of the above positions.

Manual Transmission ...

Auto operation does not operate but manual operate normally

(driver side)

Diagnosis Procedure

1.PERFORM INITIALIZATION PROCEDURE

Initialization procedure is executed and operation is confirmed.

Refer to PWC-16, "Work Procedure".

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK ENCODER CIRCUIT

Check encoder c ...