Nissan Juke Service and Repair Manual : ASCD main switch

Component Function Check

1.CHECK ASCD MAIN SWITCH FUNCTION

With CONSULT-III

With CONSULT-III

1. Turn ignition switch ON.

2. Select “ENGINE” using CONSULT-III.

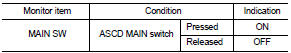

3. Select “MAIN SW” in “DATA MONITOR” mode.

4. Check “MAIN SW” indication under the following condition.

Without CONSULT-III

Without CONSULT-III

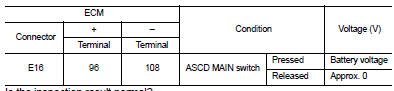

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector and ground under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Go to EC-768, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E21 and E38. Refer to Ground Inspection in GI-44, "Circuit Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair or replace ground connection.

2.CHECK ASCD MAIN SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination switch (spiral cable) harness connector.

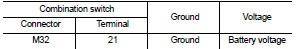

3. Turn ignition switch ON.

4. Check the voltage between combination switch harness connector and ground.

5. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 4.

NO >> GO TO 3.

3.DETECT MALFUNCTIONING PART

Check the following.

• 10 A fuse (No. 3)

• Combination switch (spiral cable)

• Harness for open and short between combination switch and fuse

>> Repair open circuit, short to ground or short to power in harness or connectors.

4.CHECK ASCD MAIN SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

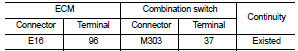

1. Disconnect ECM harness connector.

2. Check the continuity between ECM harness connector and combination switch harness connector.

3. Also check harness for short to ground and short to power.

Is the inspection result normal? YES >> GO TO 6.

NO >> GO TO 5.

5.DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E105, M77 • Combination switch (spiral cable) • Harness for open and short between ECM and combination switch

>> Repair open circuit, short to ground or short to power in harness or connectors.

6.CHECK ASCD STEERING SWITCH

Refer to EC-769, "Component Inspection (ASCD STEERING SWITCH)".

Is the inspection result normal? YES >> GO TO 7.

NO >> Replace ASCD steering switch.

7.CHECK INTERMITTENT INCIDENT

1. Refer to GI-42, "Intermittent Incident".

Is the inspection result normal? YES >> Replace IPDM E/R.

NO >> Repair open circuit, short to ground or short to power in harness or connectors.

Component Inspection (ASCD STEERING SWITCH)

1.CHECK ASCD STEERING SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect combination switch (spiral cable) harness connector.

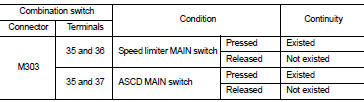

3. Check the continuity between combination switch harness connector terminals under the following condition.

Is the inspection result normal? YES >> GO TO 2.

NO >> Replace ASCD steering switch.

2.CHECK ASCD STEERING SWITCH-II

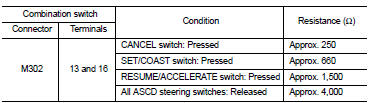

Check resistance between combination switch (spiral cable) harness connector terminals under the following conditions.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace ASCD steering switch.

ASCD indicator

ASCD indicator

Component Function Check

1.CHECK ASCD INDICATOR FUNCTION

Check ASCD indicator under the following conditions.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Go to EC-7 ...

Clutch pedal position switch

Clutch pedal position switch

Component Function Check

1.CHECK CLUTCH PEDAL POSITION SWITCH FUNCTION

With CONSULT-III

1. Turn ignition switch ON.

2. Select “ENGINE” using CONSULT-III.

3. Select “CLUTCH P/P SW” in “DATA MONITO ...

Other materials:

Back door does not opened

Diagnosis Procedure

1.CHECK BACK DOOR OPENER SWITCH

Check back door opener switch.

Refer to DLK-384, "Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning parts.

2.CHECK BACK DOOR OPENER ACTUATOR

...

MR16DDT : Inspection and Adjustment

INSPECTION

Magnetic Switch Check

• Before starting to check, disconnect the battery cable from the negative

terminal.

• Disconnect “M” terminal of starter motor.

1. Continuity test [between “S” terminal (A) and switch body]

B : “B” terminal

C : “M” terminal

• Replace magnetic switch if co ...

Push-button ignition switch operation

When the ignition switch is pushed without depressing the brake pedal (Continuously

Variable Transmission models) or the clutch pedal (manual transmission models),

the ignition switch position will change as follows: • Push once to change to ACC.

• Push two times to change to ON.

• Push thre ...