Nissan Juke Service and Repair Manual : C1166, C1167 SV system

DTC Logic

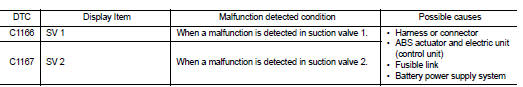

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ABS”.

Is DTC “C1166” or “C1167” detected? YES >> Proceed to BRC-197, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

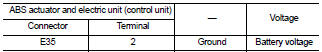

1.CHECK CUT VALVE POWER SUPPLY

1. Turn the ignition switch OFF.

2. Disconnect ABS actuator and electric unit (control unit) harness connector.

3. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

4. Turn the ignition switch ON.

CAUTION:4. Turn the ignition switch ON.

CAUTION: Never start engine.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Never start engine.

5. Check voltage between ABS actuator and electric unit (control unit) harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

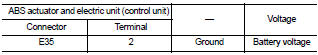

2.CHECK CUT VALVE POWER SUPPLY CIRCUIT

1. Turn the ignition switch OFF.

2. Check 50 A fusible link (I).

3. Check continuity and short circuit between ABS actuator and electric unit (control unit) harness connector terminal (2) and 50 A fusible link (I).

Is the inspection result normal? YES >> Perform trouble diagnosis for battery power supply. Refer to PG-10, "Wiring Diagram - BATTERY POWER SUPPLY -".

NO >> Repair or replace error-detected parts.

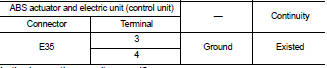

3.CHECK CUT VALVE GROUND CIRCUIT

1. Turn the ignition switch OFF.

2. Check continuity between ABS actuator and electric unit (control unit) harness connector and the ground

Is the inspection result normal? YES >> GO TO 4.

NO >> Repair or replace error-detected parts.

4.CHECK TERMINAL

Check ABS actuator and electric unit (control unit) pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-233, "Removal and Installation".

NO >> Repair or replace error-detected parts.

C1164, C1165 CV system

C1164, C1165 CV system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

C1176 stop lamp SW2

C1176 stop lamp SW2

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Microphone signal circuit

Description

Power is supplied from NAVI control unit to microphone. The microphone

transmits the sound voice to the

NAVI control unit.

Diagnosis Procedure

1.CHECK CONTINUITY BETWEEN NAVI CONTROL UNIT AND MICROPHONE CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect NAVI control unit connecto ...

Plug

Description

Replace the O-ring if oil leakage or exudes from the plug.

Exploded View

1. Plug

2. O-ring

3. O-ring

4. Plug

: Always replace after every

disassembly.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: Genuine NISSAN CVT Fluid NS-2

Removal and Insta

NOTE:

Replace the O-rings if ...

Thermostat

Exploded View

1. Thermostat housing

2. Gasket

3. Rubber ring

4. Thermostat

5. Water inlet

6. Clamp

7. Radiator hose (upper)

A. To radiator

Engine front

: N·m (kg-m, ft-lb)

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

1. Drain engine coolant from ...