Nissan Juke Service and Repair Manual : Clutch master cylinder

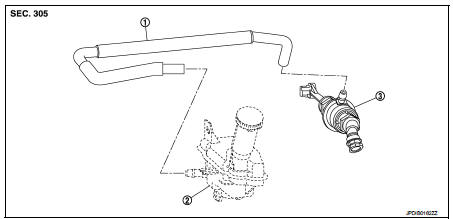

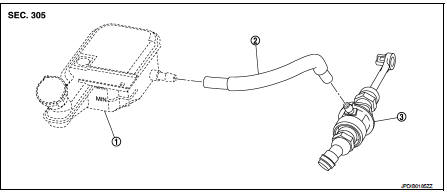

LHD : Exploded View

1. Reservoir hose

2. Reservoir tank

3. Master cylinder

LHD : Removal and Installation

REMOVAL

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

• Never disassemble clutch master cylinder.

1. Drain clutch fluid. Refer to CL-10, "RS5F92R : Draining" (RS5F92R) or CL-13, "RS6F94R : Draining" (RS6F94R).

2. Remove air cleaner case. Refer to EM-26, "Removal and Installation" (MR16DDT), EM-161, "Removal and Installation" (HR16DE), or EM-280, "Removal and Installation" (K9K).

3. Remove reservoir hose from reservoir tank and master cylinder.

4. Remove master cylinder rod end (

) from clutch pedal.

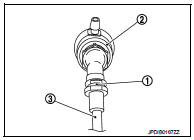

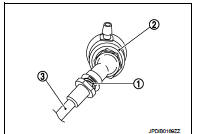

5. Pull up the lock pin (1) from connector of master cylinder (2) and separate clutch tube (3).

6. Rotate master cylinder clockwise by 45 degrees, and then remove master cylinder from the vehicle.

INSTALLATION

CAUTION:

Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

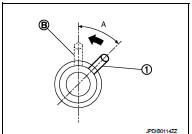

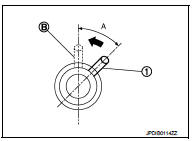

1. Tilt master cylinder clockwise by 45 degrees (A) and insert it to the mounting hole. Rotate counterclockwise and secure it. At this time, nipple (1) is upward of the vehicle.

B : Mounting condition

2. Install master cylinder rod end to clutch pedal.

CAUTION:

Press master cylinder rod end into clutch pedal until it

stops.

3. Install reservoir hose to reservoir tank and master cylinder.

CAUTION:

Set reservoir hose with painted mark facing upward.

4. Press down the lock pin into connector of master cylinder until it stops.

5. Install clutch tube into connector of master cylinder until it stops.

6. For the next step and after, install in the reverse order of removal.

LHD : Inspection and Adjustment

INSPECTION AFTER INSTALLATION

• Check the fluid leakage and the fluid level. Refer to CL-10, "RS5F92R : Inspection" (RS5F92R) or CL-13, "RS6F94R : Inspection" (RS6F94R).

• Check the clutch pedal height, clutch pedal height at clutch disengagement, and clutch pedal play. Refer to CL-7, "Inspection and Adjustment".

• Check the clutch interlock switch position. (With push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

• Check the clutch pedal position switch position. (With ASCD or with push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

ADJUSTMENT AFTER INSTALLATION

• Adjust the clutch interlock switch position. (With push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

• Adjust the clutch pedal position switch position. (With ASCD or with push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

• Perform the air bleeding. Refer to CL-12, "RS5F92R : Air Bleeding" (RS5F92R) or CL-15, "RS6F94R : Air Bleeding" (RS6F94R).

RHD

RHD : Exploded View

1. Reservoir tank

2. Reservoir hose

3. Master cyl

RHD : Removal and Installation

REMOVAL

CAUTION:

• Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

• Never disassemble clutch master cylinder.

1. Drain clutch fluid. Refer to CL-10, "RS5F92R : Draining" (RS5F92R) or CL-13, "RS6F94R : Draining" (RS6F94R).

2. Move the fuel feed tube and the fuel return hose aside not to interfere with

work. (K9K)

3. Remove reservoir hose from reservoir tank and master cylinder.

4. Remove master cylinder rod end (

) from clutch pedal.

5. Remove the engine room insulator.

6. Remove the cowl top extension. Refer to EXT-20, "Removal and Installation".

7. Pull up the lock pin (1) from connector of master cylinder (2) and separate clutch tube (3).

8. Rotate master cylinder clockwise by 45 degrees, and then remove master cylinder from the vehicle.

INSTALLATION

CAUTION

:

Keep painted surface on the body or other parts free of clutch fluid. If it

spills, wipe up immediately

and wash the affected area with water.

1. Tilt master cylinder clockwise by 45 degrees (A) and insert it to the mounting hole. Rotate counterclockwise and secure it. At this time, nipple (1) is upward of the vehicle.

B : Mounting condition

2. Install master cylinder rod end to clutch pedal.

CAUTION:

Press master cylinder rod end into clutch pedal until it

stops.

3. Install reservoir hose to reservoir tank and master cylinder.

4. Press down the lock pin into connector of master cylinder until it stops.

5. Install clutch tube into connector of master cylinder until it stops.

6. Install the fuel feed tube and the fuel return hose. (K9K) 7. Fill with clutch fluid. Refer to CL-11, "RS5F92R : Refilling" (RS5F92R) or CL-14, "RS6F94R : Refilling" (RS6F94R).

8. Install the engine room insulator.

9. Install the cowl top extension. Refer to EXT-20, "Removal and Installation".

RHD : Inspection and Adjustment

INSPECTION AFTER INSTALLATION

• Check the fluid leakage and the fluid level. Refer to CL-10, "RS5F92R : Inspection" (RS5F92R) or CL-13, "RS6F94R : Inspection" (RS6F94R).

• Check the clutch pedal height, clutch pedal height at clutch disengagement, and clutch pedal play. Refer to CL-7, "Inspection and Adjustment".

• Check the clutch interlock switch position. (With push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

• Check the clutch pedal position switch position. (With ASCD or with push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

ADJUSTMENT AFTER INSTALLATION

• Adjust the clutch interlock switch position. (With push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

• Adjust the clutch pedal position switch position. (With ASCD or with push-button ignition switch system) Refer to CL-7, "Inspection and Adjustment".

• Perform the air bleeding. Refer to CL-12, "RS5F92R : Air Bleeding" (RS5F92R) or CL-15, "RS6F94R : Air Bleeding" (RS6F94R)

Clutch pedal

Clutch pedal

LHD : Exploded View

1. Clutch pedal

2. Stopper rubber

3. Clip

4. Clutch interlock switch *1

5. Clutch pedal position switch *2

6. Pedal pad

7. Pedal stopper rubber

*1 : With push-button ...

Clutch piping

Clutch piping

Exploded View

RS5F92R

1. CSC (Concentric Slave Cylinder)

2. Clutch tube

3. Clutch damper

4. Bracket

5. Master cylinder

RS6F94R

1. CSC (Concentric Slave Cylinder)

2. Clutch tube

3. C ...

Other materials:

U0140 lost communication (BCM)

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...

Rear power window switch

Component Function Check

1. CHECK REAR POWER WINDOW SWITCH FUNCTION

Check rear power window motor operation with rear power window switch.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Refer to PWC-24, "Diagnosis Procedure".

Diagnosis Procedure

1.CHECK R ...

Door motor

Exploded View

LEFT SIDE

1. A/C unit assembly

2. Intake door lever

3. Intake door link

4. Intake door motor

5. Air mix door motor

6. Air mix door link

7. Max. cool door

8. Upper air mix door lever

9. Air mix door rod

10. Lower air mix door lever

RIGHT SIDE

1. A/C unit assembly ...