Nissan Juke Service and Repair Manual : C1155 brake fluid level switch

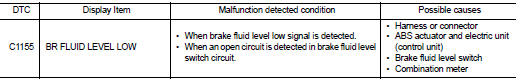

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT-III.

With CONSULT-III.

1. Turn the ignition switch OFF to ON.

2. Perform self-diagnosis for “ABS”.

Is DTC “C1155” detected? YES >> Proceed to BRC-192, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis Procedure

1.CHECK BRAKE FLUID LEVEL

1. Turn the ignition switch OFF.

2. Check brake fluid level.

- LHD: Refer to BR-12, "Inspection".

- RHD: Refer to BR-80, "Inspection".

Is the inspection result normal? YES >> GO TO 2.

NO >> Refill brake fluid.

• LHD: Refer to BR-12, "Refilling".

• RHD: Refer to BR-80, "Refilling".

2.PERFORM SELF-DIAGNOSIS (1)

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Turn the ignition switch ON.

CAUTION:

Never start the engine.

4. Perform self-diagnosis for “ABS”.

Is DTC “C1155” detected? YES >> INSPECTION END

NO >> GO TO 3.

3.CHECK BRAKE FLUID LEVEL SWITCH

Check brake fluids level switch. Refer to BRC-194, "Component Inspection".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Replace reservoir tank. GO TO 4.

• LHD: Refer to BR-44, "Disassembly and Assembly".

• RHD: Refer to BR-109, "Disassembly and Assembly".

4.PERFORM SELF-DIAGNOSIS (2)

With CONSULT-III.

With CONSULT-III.

1. Erase Self-diagnosis result for “ABS”.

2. Turn the ignition switch OFF, and wait 10 seconds or more.

3. Turn the ignition switch ON.

CAUTION:

Never start the engine.

4. Perform self-diagnosis for “ABS”.

Is DTC “C1155” detected? YES >> INSPECTION END

NO >> GO TO 5.

5.CHECK CONNECTOR AND TERMINAL

1. Turn the ignition switch OFF.

2. Disconnect brake fluid level switch harness connector.

3. Check brake fluid level switch harness connector for disconnection or looseness.

4. Check brake fluid level switch pin terminals for damage or loose connection with harness connector.

5. Disconnect combination meter harness connector.

6. Check combination meter harness connector for disconnection or looseness.

7. Check combination meter pin terminals for damage or loose connection with harness connector.

Is the inspection result normal? YES >> GO TO 7.

NO >> Repair or replace error-detected parts. GO TO 6.

6.PERFORM SELF-DIAGNOSIS (3)

With CONSULT-III.

With CONSULT-III.

1. Connect brake fluid level switch harness connector.

2. Connect combination meter harness connector.

3. Erase Self-diagnosis result for “ABS”.

4. Turn the ignition switch OFF, and wait 10 seconds or more.

5. Turn the ignition switch ON.

CAUTION:

Never start the engine.

6. Perform self-diagnosis for “ABS”.

Is DTC “C1155” detected? YES >> INSPECTION END

NO >> GO TO 7.

7.CHECK BRAKE FLUID LEVEL SWITCH HARNESS

1. Turn the ignition switch OFF.

2. Disconnect brake fluid level switch harness connector.

3. Disconnect combination meter harness connector.

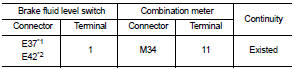

4. Check continuity between brake fluid level switch harness connector and combination meter harness connector.

*1: 4WD

*2: 2WD

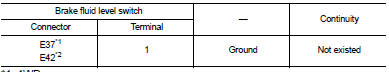

5. Check continuity between brake fluid level switch harness connector and ground.

*1: 4WD

*2: 2WD

Is the inspection result normal? YES >> GO TO 8.

NO >> Repair or replace error-detected parts. GO TO 8.

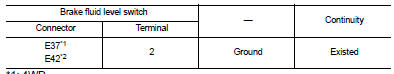

8.CHECK BRAKE FLUID LEVEL SWITCH GROUND

Check continuity between brake fluid level switch harness connector and ground.

*1: 4WD

*2: 2WD

Is the inspection result normal? YES >> GO TO 9.

NO >> Repair or replace error-detected parts. GO TO 9.

9.CHECK COMBINATION METER

Check combination meter. Refer to MWI-23, "CONSULT-III Function".

Is the inspection result normal? YES >> Replace ABS actuator and electric unit (control unit). Refer to BRC-233, "Removal and Installation".

NO >> Repair or replace combination meter. Refer to MWI-69, "Removal and Installation".

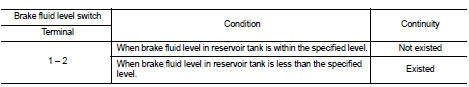

Component Inspection

1.CHECK BRAKE FLUID LEVEL SWITCH

1. Turn the ignition switch OFF.

2. Disconnect brake fluid level switch harness connector.

3. Check continuity between terminals of brake fluid level switch.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace reservoir tank.

• LHD: Refer to BR-44, "Disassembly and Assembly".

• RHD: Refer to BR-109, "Disassembly and Assembly".

C1144 incomplete steering angle sensor adjustment

C1144 incomplete steering angle sensor adjustment

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

C1164, C1165 CV system

C1164, C1165 CV system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 ...

Other materials:

Engine oil

Inspection

OIL LEVEL AND MUDDINESS

• Before starting the engine, check the oil level placing vehicle

horizontally.

If the engine is already started, stop it and allow 10 minutes

before checking.

• Make sure the oil level is within the range shown in the figure.

• If it is out of range, adj ...

B2321, B2322 oil level sensor

Description

The oil level sensor detects the level of engine oil, and then transmits the

oil level signal to the combination

meter.

DTC Logic

DTC DETECTION LOGIC

NOTE:

When the following conditions are satisfied, the combination meter reads the

resistance value of oil level sensor.

Th ...

A/C auto AMP. Connection recognition signal circuit

Diagnosis Procedure

1.CHECK A/C AUTO AMP. CONNECTION RECOGNITION SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector and ground.

Is the inspection result normal?

YES >> INSPECTION END

NO >> GO TO 2.

2.CHECK A/C AUTO AMP. CONNECTION R ...