Nissan Juke Service and Repair Manual : Back door opener actuator

Diagnosis Procedure

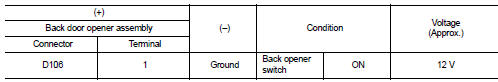

1.CHECK BACK DOOR OPENER ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect back door opener assembly connector.

3. Check voltage between back door opener assembly harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> GO TO 2.

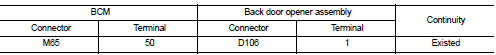

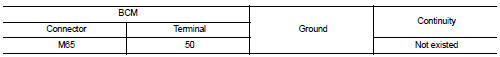

2.CHECK BACK DOOR OPENER ACTUATOR CIRCUIT

1. Disconnect BCM connector.

2. Check continuity between BCM harness connector and back door opener assembly harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> Replace BCM. Refer to BCS-161, "Removal and Installation".

NO >> Repair or replace harness.

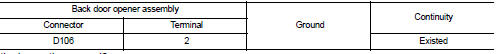

3.CHECK BACK DOOR OPENER ACTUATOR GROUND CIRCUIT

Check continuity between back door opener assembly harness connector and ground.

Is the inspection normal? YES >> Replace back door opener assembly.

NO >> Repair or replace harness.

Back door opener switch

Back door opener switch

Component Function Check

1.CHECK FUNCTION

1. Select “TRUNK” of “BCM” using CONSULT-III.

2. Select “TRNK OPNR SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to t ...

Other materials:

Navigation system

Symptom Table

RELATED TO NAVIGATION

NOTE:

Combined part of AV switch and NAVI control unit.

RELATED TO HANDS-FREE PHONE

• Check that the cellular phone is the corresponding type (Bluetooth™

enabled) and Bluetooth™ turns ON.

• Malfunction may occur due to the version change of the phone typ ...

Idle air volume learning

Description

Idle Air Volume Learning is a function of ECM to learn the idle air volume

that keeps each engine idle speed

within the specific range. It must be performed under any of the following

conditions:

• Each time electric throttle control actuator or ECM is replaced.

• Idle speed or i ...

Exploded View

1. Final drive mounting bracket

2. Washer

3. Rear final drive assembly

: Vehicle front

: N·m (kg-m, ft-lb)

: Never reuse parts

: Apply multi purpose grease

: Apply gear oil.

...