Nissan Juke Service and Repair Manual : 5TH injector

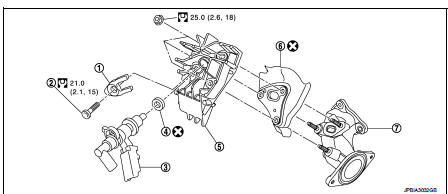

Exploded View

1. 5th injector retaining bracket

2. 5th injector bolt

3. 5th injector

4. Injector seal

5. Diesel injector cooler

6. Gasket

7. Turbocharger outlet duct

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

CAUTION:

• Be sure to read "Precautions for diesel equipment". Refer to EM-263,

"Precaution for Diesel Equipment".

• Make preparations for coolant outflow.

1. Remove air cleaner case. Refer to EM-280, "Exploded View".

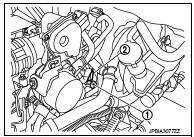

2. Disconnect quick connector(1) and harness connector (2).

CAUTION:

• Be careful not to damage the connector.

• Be sure to read "Precautions for diesel equipment". Refer to EM-263, "Precaution for Diesel Equipment"

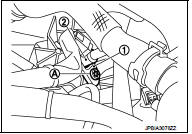

3. Remove the following parts from the upper side of the engine.

• Remove fixing bolt (A) of 5th injector retaining bracket (1) • Remove 5th injector retaining bracket (1).

4. Remove the 5th injector (2) and injector seal. Refer to EM-296, "Exploded View"

INSTALLATION

1. Clean the 5th injector: • Immerse the 5th injector in a container of diesel.

• Wipe using clean cloth.

CAUTION:

Never clean the 5th injector with:

• A wire brush,

• An emery cloth,

• An ultrasonic cleaner.

2. Always replace the injector seal.

3. Install the 5th injector, injector seal and 5th injector retaining bracket assembly.

CAUTION:

Before tightening the 5th injector retaining bracket, check that the 5th

injector is correctly positioned

in relation to the bracket.

4. Install the other parts in the reverse order of the removal.

Injection tube and fuel injector

Injection tube and fuel injector

Exploded View

1. Spill hose

2. Injection tube

3. Fuel injector

4. Heat protection washer

5. Fuel injector bracket

6. Fuel injector bracket spacer

7. Fuel rail stud bolt

8. Fuel rail

9 ...

High pressure supply pump

High pressure supply pump

Exploded View

1. High pressure supply pump protector

2. High pressure supply pump

: N·m (kg-m, ft-lb)

Removal and Installation

REMOVAL

CAUTION:

• Be sure to read “Precautions for Diesel Equi ...

Other materials:

Unlock sensor

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “LOCK STATUS” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Unlock sensor is OK. ...

Yaw rate/side/decel G sensor

Exploded View

1. Yaw rate/side/decel G sensor

2. Yaw rate/side/decel G sensor harness

connector

3. Bracket

: Vehicle front

: N·m (kg-m, in-lb)

Removal and Installation

REMOVAL

CAUTION:

Never drop or strike yaw rate/side/decel G sensor, because it has little

endurance to impact. Never ...

P1651 starter motor relay

Description

ECM controls ON/OFF state of the starter relay, according to the engine and

vehicle condition. Models with no

Intelligent Key System transmit a control signal directly to IPDM E/R. On the

other hand, models with the Intelligent

Key System transmit a control signal to IPDM E/R by w ...