Nissan Juke Service and Repair Manual : Injection tube and fuel injector

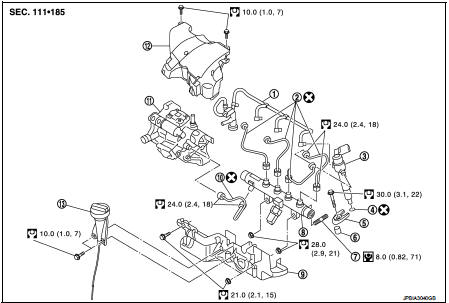

Exploded View

1. Spill hose

2. Injection tube

3. Fuel injector

4. Heat protection washer

5. Fuel injector bracket

6. Fuel injector bracket spacer

7. Fuel rail stud bolt

8. Fuel rail

9. High pressure protection cover (lower)

10. Injection tube

11. High pressure supply pump

12. High pressure protection cover (upper)

13. Oil level gauge guide

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

Removal and Installation

REMOVAL

CAUTION:

• Be sure to read “Precautions for Diesel Equipment”. Refer to EM-263,

"Precaution for Diesel Equipment".

• Wait until the fuel temperature drops before carrying out any work.

• Order the special high pressure injection circuit plug kit.

• It is forbidden to open an injector. If you open an injector by mistake, you will have to change it. This is because of the manufacturing and installation tolerances and because there is a risk of contaminating the inside of the injector.

• The rod filter of the injector must not be removed.

NOTE:

It is possible to replace a single injection tube.

1. Disconnect the battery cable from negative terminal.

2. Remove air inlet tube assembly and air inlet tube. Refer to EM-281, "Exploded View".

3. Remove oil level gauge guide and plug the hole.

4. Remove injection tube protection cover.

5. Remove the neck located on the fuel rail, NOTE

:

Undo the nut on the pump side or the injector side, then the nut located on the

rail side. Undo the

nuts for each pipe in turn. Move the nut along the pipe keeping the olive in

contact with the taper.

6. Remove all the injection tubes.

7. Plug all the holes in the injection circuit.

8. Remove fuel rail.

9. Disconnect fuel return pipe.

10. Manually remove the injector diesel return hose.

CAUTION:

Do not force on the diesel injector return hose

11. Plug all the holes of the injection circuit.

12. Disconnect the injector harness connector.

13. Unscrew the injector bracket.

14. Remove the injector.

15. Pull off the flame shield washer.

INSTALLATION

CAUTION:

All the injection tubes removed must be systematically replaced.

1. Clean the injector sockets and the injector bodies, as well as their brackets using a lint-free cloth (use the wipes recommended for this purpose, dipped in clean solvent.

2. Dry off using a different new wipe.

3. Replace the flame shield washer with a new one.

4. Position the injector.

5. Tighten its mounting bracket.

: 30.0 N·m (3.1 kg-m, 22 ft-lb)

: 30.0 N·m (3.1 kg-m, 22 ft-lb)

6. Install injection tubes with new one.

7. Finger tightens the nuts.

8. Before fitting the new injection tubes, lightly lubricate the nut threads with the oil from the sachet provided in the new parts kit.

NOTE

:

Fit the pump/rail pipe before the rail/injector tubes.

9. Fit the pump-rail injection tube as follow: • Remove the protective plugs from the high pressure pump outlet, the high pressure rail inlet and the pipe.

• Insert the injection tube olive into the taper of the high pressure pump

outlet,

• Insert the injection tube olive into the taper of the high pressure rail

inlet.

• Finger tighten the nuts of the injection tube starting with the one located on the rail side.

10. Install the rail-injector injection tube.

11. Tighten the injection tube nut.

: 24.0 N·m (2.4 kg-m, 18 ft-lb)

: 24.0 N·m (2.4 kg-m, 18 ft-lb)

12. Connect fuel return pipe.

13. Install in the reverse order to removal for the other refitting operations.

Vacuum pump

Vacuum pump

Exploded View

1. Vacuum pump

2. Gasket

3. Damper valve bracket

4. Vacuum hose

A. To electric throttle control actuator

Engine front

: N·m (kg-m, ft-lb)

: Always replace after every

disa ...

5TH injector

5TH injector

Exploded View

1. 5th injector retaining bracket

2. 5th injector bolt

3. 5th injector

4. Injector seal

5. Diesel injector cooler

6. Gasket

7. Turbocharger outlet duct

: N·m (kg-m, ft-lb)

...

Other materials:

Side oil seal

Removal and Installation

REMOVAL

1. Remove front drive shafts. Refer to FAX-53, "Removal and Installation".

2. Remove differential side oil seals (1) from clutch housing and

transaxle case, using an oil seal remover.

CAUTION:

Never damage transaxle case and clutch housing.

INSTA ...

U1000 can comm circuit

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each co ...

Off position warning does not operate

Diagnosis Procedure

1.CHECK DTC WITH BCM AND COMBINATION METER

Check that DTC is not detected with BCM and combination meter.

Is the inspection result normal?

YES >> GO TO 2.

NO-1 >> Refer to BCS-67, "DTC Index". (BCM)

NO-2 >> Refer to MWI-36, "DTC Index&qu ...