Nissan Juke Service and Repair Manual : Writing unit parameter

Description

Perform writing unit parameter of electric controlled coupling after replacing 4WD control module, rear final drive assembly or electric controlled coupling. Refer to DLN-39, "Work Procedure".

Work Procedure

1.WRITE UNIT PARAMETER

With CONSULT-III

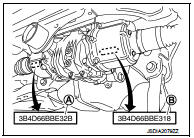

1. Confirm the unit parameter (A) of electric controlled coupling (LH) and (B) of electric controlled coupling (RH).

NOTE

:

• This illustration is sample.

• For the illustration, the unit parameters are following.

Right side: 3B4D66BBE318 Left side: 3B4D66BBE32B

2. Turn the ignition switch OFF to ON.

3. Select “UNIT CHARACTERISTICS WRITE” of CONSULT-III “WORK SUPPORT” for “ALL MODE AWD/4WD”.

4. Input unit parameters.

5. Select “Start”.

6. Check that “UNIT CHARACTERISTICS WRITE COMPLETED” is displayed.

>> WORK END

Diagnosis and repair work flow

Diagnosis and repair work flow

Work Flow

DETAILED FLOW

1.INTERVIEW FROM THE CUSTOMER

Clarify customer complaints before inspection. First of all, perform an

interview utilizing DLN-37, "Diagnostic

Work Sheet" and re ...

Other materials:

P0868 transmission fluid pressure

Description

The secondary pressure solenoid valve regulates the secondary pressure to

suit the driving condition in

response to a signal sent from the TCM.

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC CONFIRMATIO ...

U0140 lost communication (BCM)

Description

CAN (Controller Area Network) is a serial communication line for real-time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent malfunction

detection ability.

Many electronic control units are equipped onto a vehicle, and ...

Wheelarch Height

2WD

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand tools and

mats are in designated positions.

4WD

Measure value under unladen* conditions.

*: Fuel, engine coolant and lubricant are full. Spare tire, jack, hand t ...