Nissan Juke Service and Repair Manual : Wheel sensor

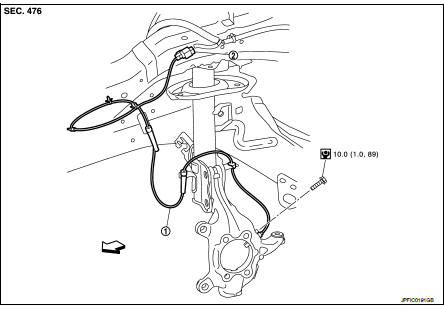

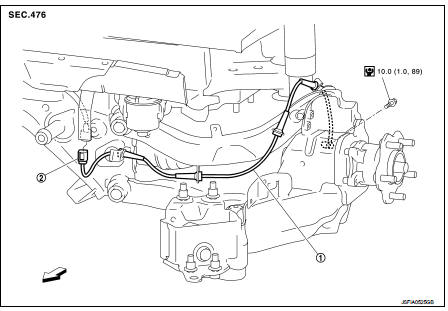

Front wheel sensor : Exploded View

1. Front LH wheel sensor 2. Front LH wheel sensor harness connector

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

NOTE:

Front RH wheel sensor is symmetrically opposite of LH.

Front wheel sensor : Removal and Installation

REMOVAL

1. Remove tires.

2. Remove the fender protector (front). Refer to EXT-22, "Removal and Installation".

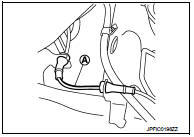

3. Remove front wheel sensor from steering knuckle.

CAUTION:

Never rotate and never pull front wheel sensor as much as possible, when pulling

out.

4. Remove front wheel sensor harness from the vehicle.

CAUTION:

Never twist or pull front wheel sensor harness, when removing.

INSTALLATION

Note the following, and install in the reverse order of the removal.

• Check that there is no foreign material like iron powder or damage on inner surface of front wheel sensor mounting hole of steering knuckle and sensor rotor. Install after cleaning when there are foreign material like iron powder, or replace when there is a malfunction.• Check that there is no foreign material like iron powder or damage on inner surface of front wheel sensor mounting hole of steering knuckle and sensor rotor. Install after cleaning when there are foreign material like iron powder, or replace when there is a malfunction.

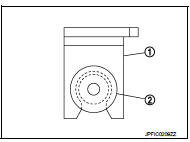

• Never twist front wheel sensor harness when installing front wheel sensor. Check that grommet (2) is fully inserted to bracket (1).

Check that front wheel sensor harness is not twisted after installation.

• Never twist front wheel sensor harness when installing front wheel sensor. Check that grommet (2) is fully inserted to bracket (1).

Check that front wheel sensor harness is not twisted after installation.

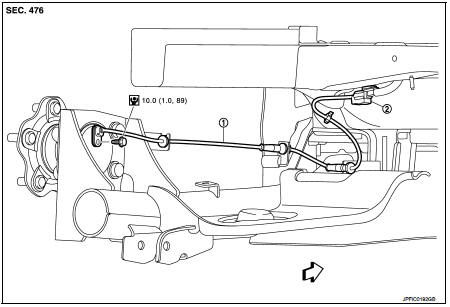

Rear wheel sensor : Exploded View

2WD

Left side

1. Rear LH wheel sensor 2. Rear LH wheel sensor harness connector

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

Right side

1. Rear RH wheel sensor 2. Rear RH wheel sensor harness connector

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

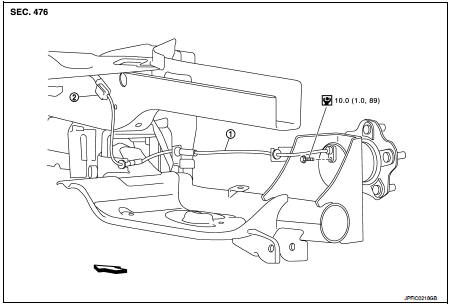

4WD

1. Rear LH wheel sensor 2. Rear LH wheel sensor harness connector

: Vehicle front

: Vehicle front

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

NOTE

:

Rear RH wheel sensor is symmetrically opposite of LH.

Rear wheel sensor : Removal and Installation

REMOVAL

1. Remove rear wheel sensor from wheel hub and bearing assembly (2WD).

CAUTION:

Never rotate or pull rear wheel sensor as much as possible, when pulling out.

2. Remove rear wheel sensor from axle housing (4WD).

CAUTION:

Never rotate or pull rear wheel sensor as much as possible, when pulling out.

3. Remove rear wheel sensor harness from the vehicle.

CAUTION:

Never twist and never pull rear wheel sensor harness, when removing.

INSTALLATION

Note the following, and install in the reverse order of the removal.

• Check that there is no foreign material like iron powder or damage on inner surface of rear wheel sensor mounting hole of wheel hub and bearing assembly and sensor rotor. Install after cleaning when there are foreign material like iron powder, or replace when there is a malfunction.

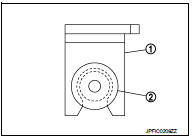

• Never twist rear wheel sensor harness when installing rear wheel sensor. Check that grommet (2) is fully inserted to bracket (1).

Check that rear wheel sensor harness is not twisted after installation.

CAUTION:

Check that the identification line (A) of the rear wheel sensor

is faced upward.

Sensor rotor

Sensor rotor

Front sensor rotor : Removal and Installatio

REMOVAL

Replace wheel hub as an assembly when replacing because sensor rotor cannot

be disassembled.

• MR16DDT: Refer to FAX-11, "Removal and I ...

Other materials:

NISSAN Advanced Air Bag System (front seats)

1. Crash zone sensor

2. Supplemental front-impact air bag modules

3. Front seat-mounted side-impact supplemental air bag modules

4. Occupant classification sensors (weight sensors)

5. Occupant classification system control unit

6. Roof-mounted curtain side-impact supplemental air bag inflator ...

Engine stand setting

Setting

NOTE:

Explained here is how to disassemble with engine stand supporting transaxle

surface. When using different

type of engine stand, note with difference in steps and etc.

1. Remove the engine and the transaxle assembly from the vehicle, and separate

the transaxle from the

engine ...

U0122 Vehicle dynamics control

module

Description

CAN (Controller Area Network) is a serial communication line for real time

application. It is an on-vehicle multiplex

communication line with high data communication speed and excellent error

detection ability. Many electronic

control units are equipped onto a vehicle, and each c ...