Nissan Juke Service and Repair Manual : Turbocharger

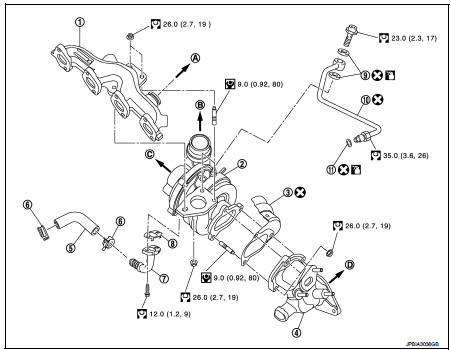

Exploded View

1. Exhaust manifold

2. Turbocharger

3. Gasket

4. Turbocharger outlet duct

5. Oil outlet hose

6. Clamp

7. Oil return pipe

8. Gasket

9. Washer

10. Oil supply tube

11. O-ring

A. To EGR tube

B. To air inlet pipe

C. To turbocharge air inlet pipe

D. To diesel particular filter assembly

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

: N·m (kg-m, in-lb)

: Always replace after every

: Always replace after every

disassembly.

: Should be lubricated with oil.

: Should be lubricated with oil.

Removal and Installation

REMOVAL

1. Remove air cleaner case. Refer to EM-280, "Exploded View".

2. Remove cowl top extension. Refer to EXT-20, "Exploded View".

3. Drain engine coolant. Refer to CO-62, "Draining".

4. Remove diesel particular filter assembly. Refer to EX-17, "Exploded View".

5. Remove EGR volume control valve housing. Refer to EM-283, "Exploded View".

6. Remove EGR cooler.

7. Disconnect 5th injector quick connector and harness connector.

8. Remove oil tubes.

9. Remove turbocharger outlet duct bracket.

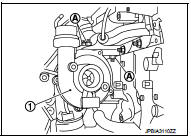

10. Remove turbocharger assembly (1) as follows:

NOTE

:

After applying penetrative lubricant to the mounting nuts, check for the

penetration of the lubricant, and

then loosen the nuts (A) to remove.

a. Remove turbocharger oil outlet hose.

CAUTION:

Be careful not to deform each turbocharger piping when pulling

out the assembly.

11. Remove turbocharger outlet duct.

INSTALLATION

Install in the reverse order of removal.

NOTE

:

Apply LOCTITE FRENETANCH or equivalent to the threads of the turbocharger oil

inlet pipe union to the cylinder

head.

Inspection

INSPECTION AFTER REMOVAL

Turbocharger

CAUTION:

When the compressor wheel, turbine wheel or rotor shaft is damaged, remove all

the fragments and

foreign matter left in the following passages in order to prevent a secondary

failure:

Suction side : Between turbocharger and air cleaner Exhaust side : Between turbocharger and outlet duct

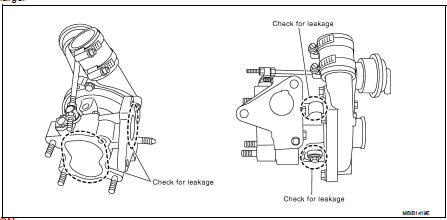

INSPECTION AFTER INSTALLATION

Start engine and raise engine speed to check no exhaust emission leaks.

EGR valve

EGR valve

Exploded View

1. EGR valve assembly

2. Clamp

3. EGR tube

4. Air inlet tube

5. O-ring

6. Gasket

7. EGR cooler

8. Gasket

9. EGR volume control valve housing

10. Gasket

11. Electric t ...

Exhaust manifold

Exhaust manifold

Exploded View

1. Exhaust gas temperature sensor 1

2. Gasket

3. Exhaust manifold

4. Exhaust gas pressure sensor 1

A. To cylinder head

: N·m (kg-m, ft-lb)

: Always replace after every

disas ...

Other materials:

Transaxle assembly

Exploded View

CASE AND HOUSING

1. Filler plug

2. Gasket

3. Transaxle case

4. Bushing

5. Snap ring

6. Oil channel

7. Oil gutter

8. Position switch

9. Bracket

10. Differential side oil seal

11. Magnet

12. Drain plug

13. Input shaft oil seal

14. Clutch housing

15. 2 way conn ...

Intelligent Keys (if so equipped)

Your vehicle can only be driven with the Intelligent Keys which are registered

to your vehicle’s Intelligent Key system components and NISSAN Vehicle Immobilizer

System components.

As many as 4 Intelligent Keys can be registered and used with one vehicle. The

new keys must be registered by a ...

Harness layout

LHD

LHD : How To Read Harness Layout

CONNECTOR SYMBOL

Main symbols of connector (in Harness Layout) are indicated in the below.

LHD : Engine Room Harness

ENGINE COMPARTMENT

PASSENGER COMPARTMENT

LHD : Engine Control Harness

HR ENGINE

MR ENGINE

K9K ENGINE

LHD : Main Harness

...