Nissan Juke Service and Repair Manual : Super lock actuator

Driver side : Component Function Check

1.CHECK FUNCTION

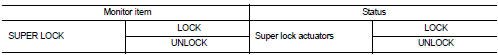

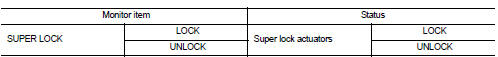

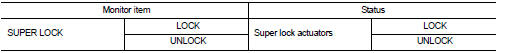

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Super lock actuator is OK.

NO >> Refer to DLK-99, "DRIVER SIDE : Diagnosis Procedure".

Driver side : Diagnosis Procedure

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

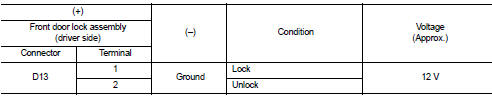

2. Disconnect front door lock assembly (driver side) connector.

3. Check voltage between front door lock assembly (driver side) harness connector and ground.

Is the inspection result normal? YES >> Replace front door lock assembly (driver side).

NO >> GO TO 2.

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

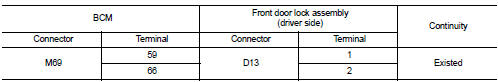

1. Disconnect BCM connector and all door lock assembly connector.

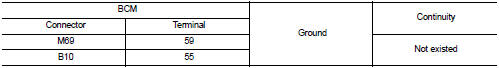

2. Check continuity between BCM harness connector and front door lock assembly (driver side) harness connector.

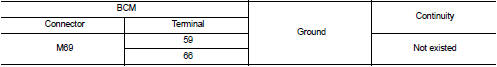

3. Check continuity between BCM harness connector and ground

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

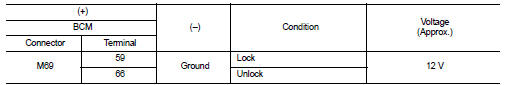

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

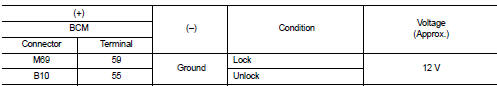

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-93, "Removal and Installation".

Passenger side : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Super lock actuator is OK.

NO >> Refer to DLK-100, "PASSENGER SIDE : Diagnosis Procedure".

Passenger side : Diagnosis Procedure

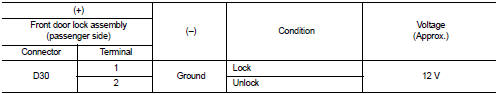

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect front door lock assembly (passenger side) connector.

3. Check voltage between front door lock assembly (passenger side) harness connector and ground.

Is the inspection result normal? YES >> Replace front door lock assembly (passenger side).

NO >> GO TO 2.

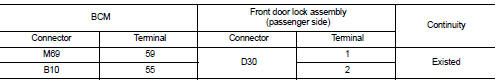

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

2. Check continuity between BCM harness connector and front door lock assembly (passenger side) harness connector

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-93, "Removal and Installation".

Rear LH : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

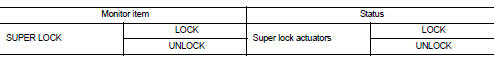

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Super lock actuator is OK.

NO >> Refer to DLK-101, "REAR LH : Diagnosis Procedure".

Rear LH : Diagnosis Procedure

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear door lock assembly LH connector.

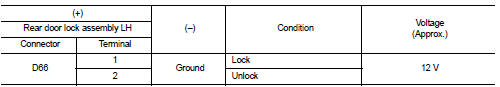

3. Check voltage between rear door lock assembly LH harness connector and ground.

Is the inspection result normal? YES >> Replace rear door lock assembly LH.

NO >> GO TO 2.

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

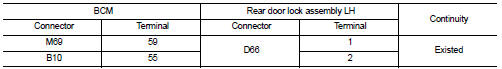

2. Check continuity between BCM harness connector and rear door lock assembly LH harness connector.

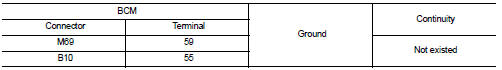

3. Check continuity between BCM harness connector and ground

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

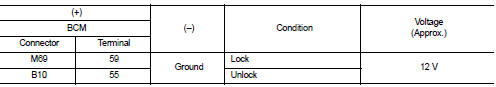

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-93, "Removal and Installation".

Rear RH : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “SUPER LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following conditions.

Is the inspection result normal? YES >> Back door lock actuator is OK.

NO >> Refer to DLK-103, "REAR RH : Diagnosis Procedure".

Rear RH : Diagnosis Procedure

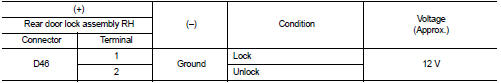

1.CHECK SUPER LOCK ACTUATOR INPUT SIGNAL

1. Turn ignition switch OFF.

2. Disconnect rear door lock assembly RH connector.

3. Check voltage between rear door lock assembly RH harness connector and ground.

Is the inspection result normal? YES >> Replace rear door lock assembly RH.

NO >> GO TO 2.

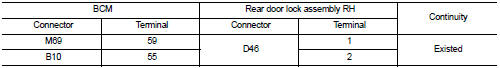

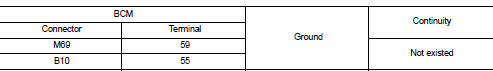

2.CHECK SUPER LOCK ACTUATOR CIRCUIT

1. Disconnect BCM connector and all door lock assembly connector.

2. Check continuity between BCM harness connector and rear door lock assembly RH harness connector.

3. Check continuity between BCM harness connector and ground.

Is the inspection result normal? YES >> GO TO 3.

NO >> Repair or replace harness.

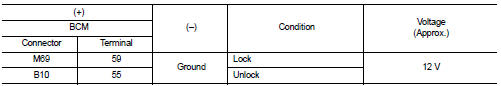

3.CHECK BCM OUTPUT SIGNAL

1. Connect BCM connector.

2. Check voltage between BCM harness connector and ground.

Is the inspection result normal? YES >> Check for internal short of each super lock actuator.

NO >> Replace BCM. Refer to BCS-93, "Removal and Installation".

Shift P warning lamp

Shift P warning lamp

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “LCD” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to t ...

Unlock sensor

Unlock sensor

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “UNLK SEN -DR” in “DATA MONITOR” mode.

3. Check that the function operates normally acco ...

Other materials:

P0740 torque converter

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

CAUTION:

Be careful of the driving speed.

1.PREPARATION BEFORE OPERATION (PART 1)

If another "DTC CONFIRMATION PROCEDURE" occurs just before, turn ignition

switch OFF and wait for at

least 10 seconds, then perform the next ...

Precaution

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT

BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”,

used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver a ...

P0697 sensor power supply

DTC Logic

DTC DETECTION LOGIC

Diagnosis Procedure

1.CHECK GROUND CONNECTION

1. Turn ignition switch OFF and wait at least 4 minutes.

2. Check ground connection E38. Refer to Ground Inspection in GI-44, "Circuit

Inspection".

Is the inspection result normal?

YES >> GO TO 2 ...