Nissan Juke Service and Repair Manual : Side oil seal

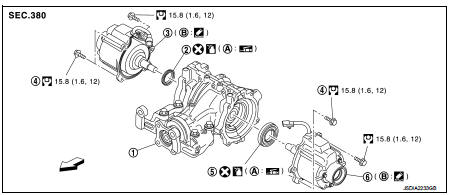

Exploded View

1. Rear final drive assembly

2. Side oil seal (right)

3. Electric controlled coupling (right)

4. Reamer bolt

5. Side oil seal (left)

6. Electric controlled coupling (left)

A. Oil seal lip B. Gear carrier mouting face

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Always replace after every

: Always replace after every

disassembly.

: Apply multi purpose grease

: Apply multi purpose grease

: Apply gear oil.

: Apply gear oil.

: Apply Genuine Liquid Gasket 1217

: Apply Genuine Liquid Gasket 1217

or equivalent.

Removal and Installation

REMOVAL

1. Remove electric controlled couplings. Refer to DLN-139, "Removal and Installation".

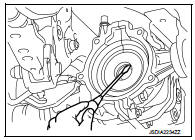

2. Remove side oil seals with a suitable tool.

CAUTION:

Never damage gear carrier and rear cover.

INSTALLATION

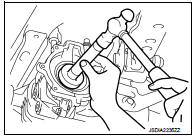

1. Install side oil seal (right side) until it becomes flush with the carrier end, using the drift (A) (SST: KV38100200).

CAUTION:

• Never reuse oil seals.

• When installing, never incline oil seals.

• Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal

.

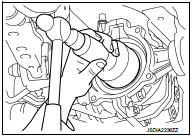

2. Install side oil seal (left side) until it becomes flush with the carrier end, using the drift (A) (SST: KV38100500).

CAUTION:

• Never reuse oil seals.

• When installing, never incline oil seals.

• Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

3. Install electric controlled couplings. Refer to DLN-139, "Removal and Installation".

4. When oil leaks while removing, check oil level after the installation.

Refer to DLN-132, "Inspection".

Front oil seal

Front oil seal

Exploded View

1. Rear final drive assembly

2. Front oil seal

3. Companion flange

4. Companion flange lock nut

A. Oil seal lip

: Vehicle front

: N·m (kg-m, ft-lb)

: Never reuse parts

: App ...

Electric controlled coupling

Electric controlled coupling

Exploded View

1. Sub-harness

2. Rear final drive assembly

3. Electric controlled coupling (right)

4. Reamer bolt

5. Electric controlled coupling (left)

A. Gear carrier mouting face

: Vehic ...

Other materials:

P2162 vehicle speed sensor

Description

ECM receives a rear wheel sensor signal from ABS actuator and electric unit

(control unit) via CAN communication

to switch combustion for the direct injection gasoline system. For the direct

injection gasoline system,

refer to EC-48, "DIRECT INJECTION GASOLINE SYSTEM : System ...

Front wheel hub and knuckle

Inspection

COMPONENT PART

Check that the mounting conditions (looseness, backlash) of each component

and component conditions

(wear, damage) are normal.

WHEEL HUB ASSEMBLY (BEARING-INTEGRATED TYPE)

Check the following items, and replace the part if necessary.

• Move wheel hub assembly in ...

B1049, B1054 driver air bag module

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.CHECK SELF-DIAG RESULT

With CONSULT-III

1. Turn ignition switch ON.

2. Perform “Self Diagnostic Result” mode of “AIR BAG” using CONSULT-III.

Without CONSULT-III

1. Turn ignition switch ON.

2. Check the air bag warning lamp statu ...