Nissan Juke Service and Repair Manual : Electric controlled coupling

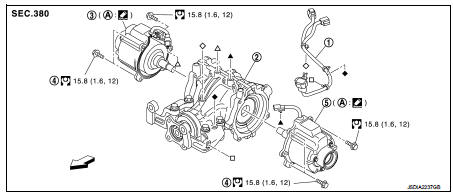

Exploded View

1. Sub-harness

2. Rear final drive assembly

3. Electric controlled coupling (right)

4. Reamer bolt

5. Electric controlled coupling (left)

A. Gear carrier mouting face

: Vehicle front

: Vehicle front

: N·m (kg-m, ft-lb)

: N·m (kg-m, ft-lb)

: Apply Genuine Liquid Gasket 1217

: Apply Genuine Liquid Gasket 1217

or equivalent.

Removal and Installation

REMOVAL

1. Remove rear drive shaft. Refer to RAX-17, "Removal and Installation".

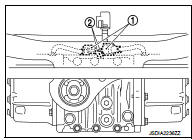

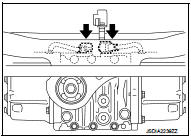

2. Disconnect electric controlled coupling connector (1) from subharness (2).

3. Remove connector clip ( ) from

) from

final drive assembly.

4. Remove electric controlled coupling from final drive assembly.

5. Remove sub-harness from final drive assembly.

CAUTION:

Remove sub-harness only when necessary.

INSTALLATION

1. Install new sub-harness clip to sub-harness.

CAUTION:

• Check original mounting dimensions to install clip to the original position.

• Baffle pin must be functioning normally.

2. Install sub-harness to final drive assembly.

CAUTION:

Check the area around the rotating object to see that there is no interference.

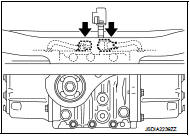

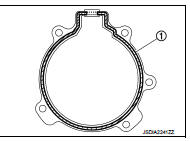

3. Apply liquid gasket (1) to mating surface of coupling cover.

CAUTION:

• Remove old gasket adhering to the mounting surfaces.

Also remove any moisture, oil, or foreign material adhering to the mounting surfaces.

• Overlap both ends of the bead for at least 3 mm (0.12 in).

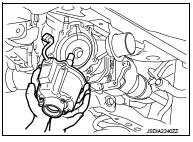

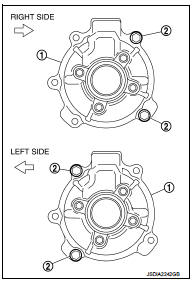

4. Install electric controlled coupling (1) to spline of stem center with grommet of harness facing upward, temporarily tighten reamer bolts (2) to the positions shown in the figure.

5. Tighten reamer bolts and coupling cover mounting bolts to the specified torque.

: Vehicle front

: Vehicle front

CAUTION:

Never allow harness to get caught in the bolt.

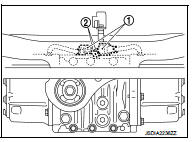

6. Install the new connector clip (

) to final drive assembly.

CAUTION:

Never reuse connector clip.

7. Connect electric controlled coupling connector (1) to sub-harness (2).

8. Install rear drive shaft. Refer to RAX-17, "Removal and Installation".

9. When oil leaks while removing, check oil level after the installation.

Refer to DLN-132, "Inspection".

10. When replacing electric controlled coupling, perform writing unit parameter. Refer to DLN-39, "Work Procedure".

Side oil seal

Side oil seal

Exploded View

1. Rear final drive assembly

2. Side oil seal (right)

3. Electric controlled coupling (right)

4. Reamer bolt

5. Side oil seal (left)

6. Electric controlled coupling (left)

A ...

Electric controlled coupling oil seal

Electric controlled coupling oil seal

Exploded View

1. Rear final drive assembly

2. Electric controlled coupling oil seal

A. Oil seal lip

: Vehicle front

: Always replace after every

disassembly.

: Apply multi purpose grease

: ...

Other materials:

Drive belt idler pulley

Removal and Installation

REMOVAL

1. Remove drive belt. Refer to EM-155, "Removal and Installation".

2. Remove the lock nut, and then remove the plate (7), idler pulley

(6), and washer (5).

1 : Alternator bracket

3. Remove the center shaft (2) together with the spacer (3) with

insert ...

Driver side power window does not operate

Diagnosis Procedure

1.CHECK FRONT POWER WINDOW MOTOR (DRIVER SIDE)

Check front power window motor (driver side).

Refer to PWC-26, "DRIVER SIDE : Component Function Check".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the malfunctioning pa ...

P1572 ASCD brake switch

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC P1572 is displayed with DTC P0605, first perform the trouble diagnosis

for DTC P0605. Refer

to EC-683, "DTC Logic".

• This self-diagnosis has the one trip detection logic. When malfunction A is

detected, DTC is not

stored in ECM memory ...