Nissan Juke Service and Repair Manual : Electric controlled coupling oil seal

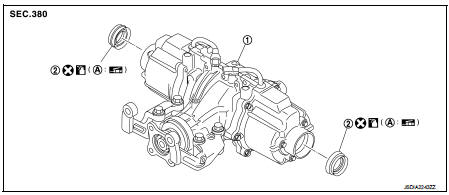

Exploded View

1. Rear final drive assembly 2. Electric controlled coupling oil seal

A. Oil seal lip

: Vehicle front

: Vehicle front

: Always replace after every

: Always replace after every

disassembly.

: Apply multi purpose grease

: Apply multi purpose grease

: Apply gear oil.

: Apply gear oil.

Removal and Installation

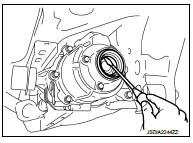

REMOVAL

1. Remove rear drive shafts. Refer to RAX-17, "Removal and Installation".

2. Remove electric controlled coupling oil seals from electric controlled coupling, using a suitable tool.

CAUTION:

Never damage electric controlled coupling.

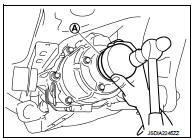

INSTALLATION

1. Install electric controlled coupling oil seals to electric controlled coupling, using the drift (A) (SST: KV38109700).

NOTE

:

The use of the special service tool satisfies the mounting dimensions.

CAUTION:

• Never reuse oil seals.

• When installing, never incline oil seals.

• Apply multi-purpose grease onto oil seal lips, and gear oil onto the circumference of oil seal.

2. Install rear drive shafts. Refer to RAX-17, "Removal and Installation".

3. When oil leaks while removing, check oil level after the installation. Refer to DLN-132, "Inspection".

Electric controlled coupling

Electric controlled coupling

Exploded View

1. Sub-harness

2. Rear final drive assembly

3. Electric controlled coupling (right)

4. Reamer bolt

5. Electric controlled coupling (left)

A. Gear carrier mouting face

: Vehic ...

Unit removal and installation

Unit removal and installation

REAR FINAL DRIVE ASSEMBLY ...

Other materials:

B209F cranking request circuit

DTC Logic

DTC DETECTION LOGIC

NOTE:

If DTC B209F is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to PCS-

30, "DTC Logic".

DTC CONFIRMATION PROCEDURE

1.PERFORM DTC CONFIRMATION PROCEDURE

1. Perform DTC CONFIRMATION PROCEDURE for DTC P1650. Re ...

Loading tips

• The GVW must not exceed GVWR or GAWR as specified on the F.M.V.S.S./

C.M.V.S.S. certification label.

• Do not load the front and rear axle to the GAWR. Doing so will exceed the GVWR.

WARNING

• Properly secure all cargo with ropes or straps to help prevent it

from sliding or shif ...

B210D starter relay

DTC Logic

DTC DETECTION LOGIC

NOTE:

• If DTC B210D is displayed with DTC U1000, first perform the trouble diagnosis

for DTC U1000. Refer to

PCS-59, "DTC Logic".

• If DTC B210D is displayed with DTC B209F, first perform the trouble diagnosis

for DTC B209F. Refer to

SEC-209, " ...