Nissan Juke Service and Repair Manual : Seat belt buckle switch signal circuit (passenger side)

Diagnosis Procedure

1.CHECK SEAT BELT BUCKLE SWITCH (PASSENGER SIDE) CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect combination meter connector and seat belt buckle switch (passenger side) connector.

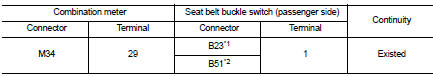

3. Check continuity between combination meter harness connector and seat belt buckle switch (passenger side) harness connector.

*1: RHD models

*2: LHD models

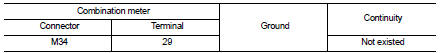

4. Check harness continuity between combination meter harness connector and ground.

Is the inspection result normal? YES >> GO TO 2.

NO >> Repair harness or connector.

2.CHECK SEAT BELT BUCKLE SWITCH (PASSENGER SIDE) GROUND CIRCUIT

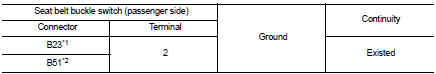

Check harness continuity between seat belt buckle switch (passenger side) harness connector and ground.

*1: RHD models

*2: LHD models

Is the inspection result normal? YES >> INSPECTION END

NO >> Repair harness or connector.

Component Inspection (Seat Belt Buckle Switch)

1.CHECK SEAT BELT BUCKLE SWITCH (PASSENGER SIDE)

1. Turn ignition switch OFF.

2. Disconnect the seat belt buckle switch (passenger side) connectors.

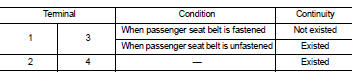

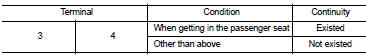

3. Check continuity between terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the seat belt buckle (passenger side). Refer to SB-8, "SEAT BELT BUCKLE : Removal and Installation".

Component Inspection (Occupant Detection Unit)

1.CHECK OCCUPANT DETECTION UNIT

1. Turn ignition switch OFF.

2. Disconnect the occupant detection unit connector.

3. Check continuity between terminals.

Is the inspection result normal? YES >> INSPECTION END

NO >> Replace the seat cushion trim and pad. Refer to SE-21, "SEAT CUSHION : Disassembly and Assembly" (2WD) or SE-29, "SEAT CUSHION : Disassembly and Assembly" (4WD).

Seat belt buckle switch signal circuit (driver side)

Seat belt buckle switch signal circuit (driver side)

Component Function Check

1.CHECK COMBINATION METER INPUT SIGNAL

Select the “Data Monitor” for the “METER/M&A” and check the “BUCKLE SW”

monitor value.

BUCKLE SW

When driver seat belt is fast ...

A/C auto AMP. Connection recognition signal circuit

A/C auto AMP. Connection recognition signal circuit

Diagnosis Procedure

1.CHECK A/C AUTO AMP. CONNECTION RECOGNITION SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector and ground.

Is the inspection res ...

Other materials:

Navigation system

Symptom Table

RELATED TO NAVIGATION

NOTE:

Combined part of AV switch and NAVI control unit.

RELATED TO HANDS-FREE PHONE

• Check that the cellular phone is the corresponding type (Bluetooth™

enabled) and Bluetooth™ turns ON.

• Malfunction may occur due to the version change of the phone typ ...

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT

PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the

driver and front passenger for certain

types of collision. Information necessary to service the system safely is

include ...

C1120, C1122, C1124, C1126 ABS in valve system

DTC Logic

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn

ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT ...