Nissan Juke Service and Repair Manual : Rear door finisher

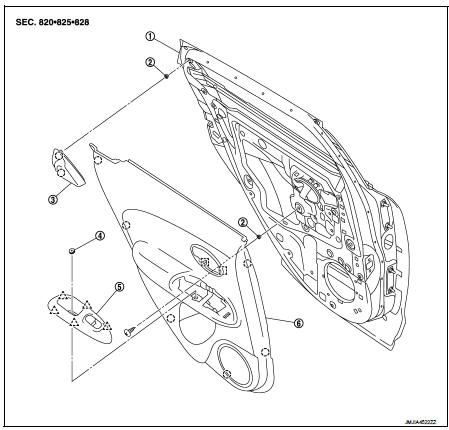

Exploded View

1. Rear door panel

2. Grommet

3. Rear door corner cover inner

4. Cap

5. Power window switch finisher

6. Rear door finisher

: Clip

: Clip

: Pawl

: Pawl

: Metal clip

: Metal clip

Removal and Installation

REMOVAL

CAUTION:

• When removing, always use a remover tool that is made of plastic.

• Never damage the door panel.

1. Fully open door window.

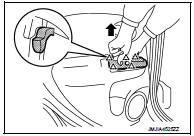

2. Remove rear corner cover inner.

Disengage rear corner cover inner fixing clips with a remover tool.

: Clip

: Clip

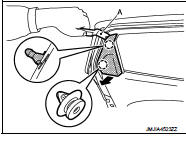

3. Remove power window switch finisher and power window switch as a unit.

1. Pull up power window switch finisher and power window switch as a unit to disengage the fixing pawls.

: Pawl

: Pawl

2. Disconnect harness connector, and then remove power window switch finisher and power window switch as a unit.

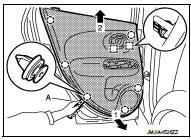

4. Remove rear door finisher fixing screw.

5. Remove rear door finisher.

1. Disengage rear door finisher fixing clips and metal clips with a remover tool (A).

: Clip

: Clip

: Metal clip

: Metal clip

2. Pull toward the direction of the arrows as shown in the figure to remove.

CAUTION:

Insert a remover tool between body side panel and clip and

disengage pawl

NOTE

:

Remove power window switch. Refer to PWC-44, "Removal and Installation".

INSTALLATION

Note the following item, and install in the reverse order of removal.

CAUTION:

When installing rear door finisher, check that clips, and metal clips are

securely in body panel holes,

and press them in.

Front door finisher

Front door finisher

Exploded View

LHD models

1. Front door panel

2. Front door finisher

3. Cap

4. Pull handle

5. Power window switch finisher

6. Pull handle bracket

: Clip

: Pawl

: Metal clip

Removal and ...

Body side trim

Body side trim

Exploded View

1. Rear body side welt

2. Center pillar upper garnish

3. Front body side welt

4. Front pillar garnish

5. Metal clip

6. Dash side finisher

7. Harness clip

8. Front kicking ...

Other materials:

Types of tires

WARNING

• When changing or replacing tires, be sure all four tires are of the same

type (Example: Summer, All Season or Snow) and construction. A NISSAN dealer may

be able to help you with information about tire type, size, speed rating and availability.

• Replacement tires may have a lower sp ...

Door lock actuator

Driver side

DRIVER SIDE : Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “DOOR LOCK” in “ACTIVE TEST” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >& ...

Door lock and unlock switch

Component Function Check

1.CHECK FUNCTION

1. Select “DOOR LOCK” of “BCM” using CONSULT-III.

2. Select “CDL LOCK SW”, “CDL UNLOCK SW” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Doo ...