Nissan Juke Service and Repair Manual : Body side trim

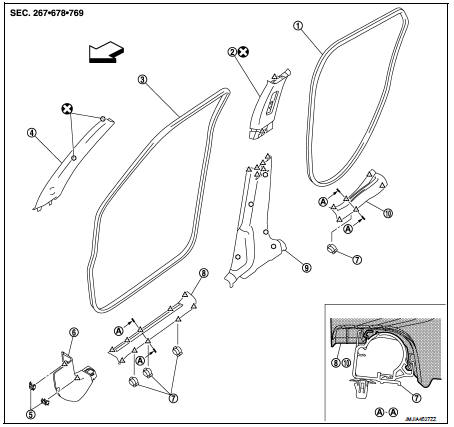

Exploded View

1. Rear body side welt

2. Center pillar upper garnish

3. Front body side welt

4. Front pillar garnish

5. Metal clip

6. Dash side finisher

7. Harness clip

8. Front kicking plate inner

9. Center pillar lower garnish

10. Rear kicking plate inner

: Clip

: Clip

: Pawl

: Pawl

: Metal clip

: Metal clip

: Vehicle front

: Vehicle front

: Do not reuse

: Do not reuse

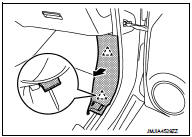

Front pillar garnish : Removal and Installation

REMOVAL

CAUTION

:

• When removing, always use a remover tool that is made of plastic.

• Never damage the body.

1. Release front pillar garnish portion of front body side welt.

2. Remove front pillar garnish.

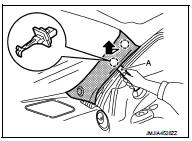

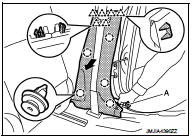

1. Disengage front pillar garnish fixing clips with a remover tool (A).

: Clip

: Clip

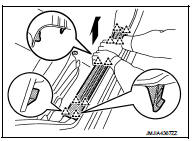

2. Twist clip portion of front pillar garnish using long nose pliers while pulling upper side of front pillar garnish toward inside, and then remove clip from front pillar garnish side.

3. Remove front pillar garnish of pull toward the arrow direction.

INSTALLATION

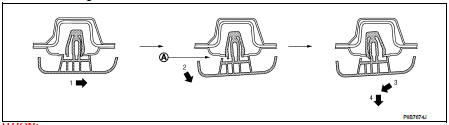

Note the following items, and install in the reverse order of removal.

CAUTION:

• When installing front pillar garnish, check that clips are securely in body

panel holes, and press

them in.

• Replace front pillar garnish with a new part after removal. Never reuse front pillar garnish.

Kicking plate inner : Removal and Installation

REMOVAL

CAUTION:

Never damage the body.

FRONT KICKING PLATE INNER

Pull up front kicking plate inner, and then disengage the pawls.

: Pawl

: Pawl

REAR KICKING PLATE INNER

Pull up rear kicking plate inner, and then disengage the pawls.

: Pawl

: Pawl

INSATALLATION

Install in the reverse order of removal.

Dash side finisher : Removal and Installation

REMOVAL

CAUTION:

Never damage the body.

1. Remove front kicking plate inner. Refer to INT-19, "KICKING PLATE INNER : Removal and Installation".

2. Pull back dash side finisher, and then disengage the pawls.

: Pawl

: Pawl

3. Disconnect dash side finisher, vehicle front side, from stud bolt and remove dash side finisher.

INSTALLATION

Install in the reverse order of removal.

Body side welt : Removal and Instal

REMOVAL

CAUTION:

• Never excessively pull body side welt.

• Never damage the body.

FRONT BODY SIDE WELT

1. Remove front kicking plate inner. Refer to INT-19, "KICKING PLATE INNER : Removal and Installation".

2. Remove front body side welt.

REAR BODY SIDE WELT

1. Remove rear kicking plate inner. Refer to INT-19, "KICKING PLATE INNER : Removal and Installation".

2. Remove rear body side welt.

INSTALLATION

Install in the reverse order of removal.

Center pillar lower garnish : Removal and Installation

REMOVAL

CAUTION:

• When removing, always use a remover tool that is made of plastic.

• Never damage the body.

1. Fully open front door and rear door.

2. Slide front seat to the fully forward position. Tilt seatback forward.

3. Remove Front body side welt and rear body side welt. Refer to INT-20, "BODY SIDE WELT : Removal and Installation".

4. Disengage center pillar lower garnish fixing clips and pawls with a remover tool (A), and then remove center pillar lower garnish.

: Clip

: Clip

: Pawl

: Pawl

INSTALLATION

Note the following item, and install in the reverse order of removal.

CAUTION:

When installing center pillar lower garnish, check that clips are securely in

body panel holes, and

press them in.

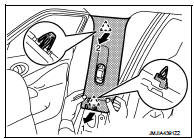

Center pillar upper garnish : Removal and Installation

REMOVAL

CAUTION:

• When removing, always use a remover tool that is made of plastic.

• Never damage the body.

1. Remove center pillar lower garnish. Refer to INT-20, "CENTER PILLAR LOWER GARNISH : Removal and Installation".

2. Remove front seat belt shoulder anchor. Refer toSB-5, "SEAT BELT RETRACTOR : Removal and Installation".

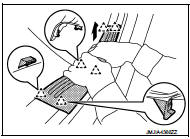

3. Disengage center pillar upper garnish lower side fixing pawl.

: Pawl

: Pawl

4. Disengage center pillar upper garnish upper side fixing clip.

NOTE

:

Removal operation can be performed easily when pressing pawl by inserting a

removal tool from direction

(A) as shown in the figure.

CAUTION:

Be careful not to apply excessive force when removing center pillar upper

garnish. Otherwise,

pawl may be damaged and fragments may drop in panel holes on body.

Note the following items, and install in the reverse order of removal.

CAUTION:

• Replace center pillar upper garnish with a new part after removal. Never reuse

center pillar upper

garnish.

• When installing center pillar upper garnish, check that pawls are securely in body panel holes, and press them in.

Rear door finisher

Rear door finisher

Exploded View

1. Rear door panel

2. Grommet

3. Rear door corner cover inner

4. Cap

5. Power window switch finisher

6. Rear door finisher

: Clip

: Pawl

: Metal clip

Removal and Installa ...

Floor trim

Floor trim

Exploded View

LHD models

1. Floor carpet

2. Carpet hook

3. Trim clip

4. Column hole cover

5. Harness clip

6. Front floor spacer RH

7. Front floor spacer LH

8. Rear floor spacer LH

9. ...

Other materials:

Driver air bag module

Exploded View

1. Steering column upper cover

2. Steering column assembly

3. Steering column lower cover

4. Side lid LH

5. TORX bolt

6. Driver air bag module

7. TORX bolt

8. Side lid RH

9. Steering wheel

10. Spiral cable

11. Steering angle sensor

12. Combination switch

13. Stee ...

Door request switch

Component Function Check

1.CHECK FUNCTION

1. Select “INTELLIGENT KEY” of “BCM” using CONSULT-III.

2. Select “REQ SW-DR”, “REQ SW-AS” in “DATA MONITOR” mode.

3. Check that the function operates normally according to the following

conditions.

Is the inspection result normal?

YES >> Fro ...

P1574 ASCD vehicle speed sensor

Description

The ECM receives two vehicle speed sensor signals via CAN communication line.

One is sent from combination

meter, and the other is from TCM (Transmission control module). The ECM uses

these signals for ASCD

control. Refer to EC-477, "AUTOMATIC SPEED CONTROL DEVICE (ASCD) : Sy ...